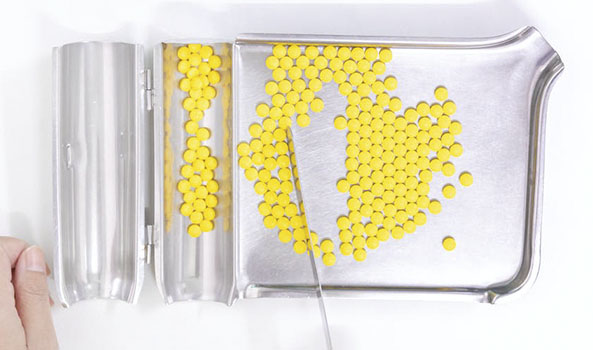

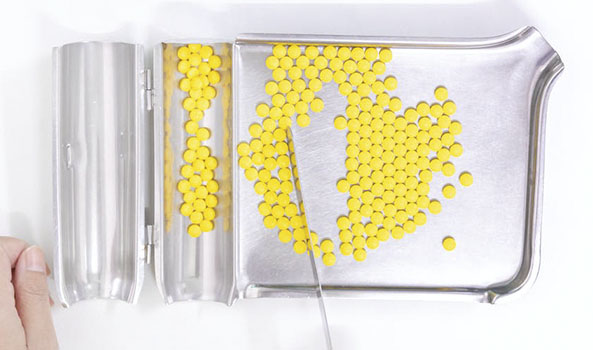

Automatic capsule counting machine It is an efficient automatic equipment, which is used to automatically count the granular materials in drug or food containers according to the preset quantity and fill them into the specified capsules. The working process of the granulator is to count and complete the filling process by passing the capsule materials through the conveying system and through the photoelectric or visual counting area. So, what are capsules and what are their classifications? Let's answer them one by one.

First, what is a granulator? The granulator is an automatic equipment, which is mainly used to accurately count and fill solid particles. Through advanced technology and design, it can complete the filling task quickly, accurately and stably. The granulator is widely used in various capsules or bagged products in medicine, food, chemical industry and other fields.

Capsule is a container used to store solid or liquid drugs, food and other substances, which is usually composed of capsule shell and capsule cover. According to the material of capsule shell, capsules can be divided into hard capsules and soft capsules. Hard capsules are usually made of gelatin and other materials, with hard texture and translucent appearance; Soft capsules are made of cellulose and other materials, with soft texture and transparent appearance. According to different internal volumes, capsules are often divided into various specifications such as No. 0, No. 1 and No. 2.

Automatic capsule counting machine The working process of is mainly to complete the counting and filling of capsule materials through the conveying system, through the photoelectric or visual counting area. When the material enters the counting area, the sensor counts the material in real time through accurate photoelectric or visual technology. Once the preset value is reached, the counter will automatically stop and send a command to make the machine stop feeding and complete the filling and sealing of capsules.

Compared with the traditional weighing and filling method, the capsule automatic counting machine has higher counting accuracy and higher production efficiency. Because the counting filling method can quickly and accurately complete the counting of solid particles, the equipment can effectively reduce production costs, improve productivity and product quality, and has been widely used.

Automatic capsule counting machine After counting several pieces, it can also complete a variety of packaging forms at the same time, such as bottled, bagged, boxed and other forms, to meet customers' different needs for packaging forms. At the same time, identification systems such as bar code or two-dimensional code can also be added to realize the unique numbering and tracking management of capsules and improve drug safety and production efficiency.