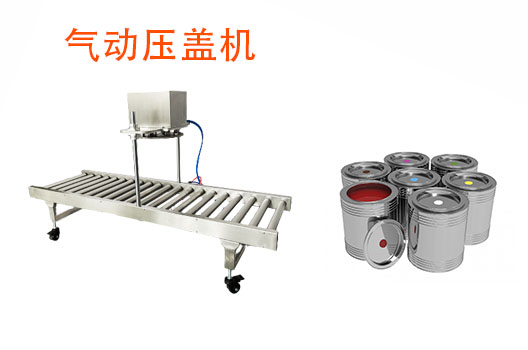

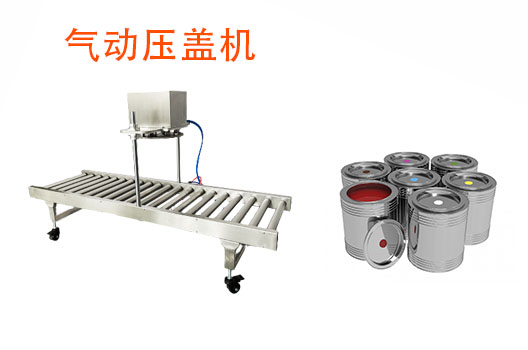

Pneumatic capping machine It is a special equipment used to press the lid of various barrel containers. When selecting professional pneumatic capping machine, the following aspects can be considered:

1. Applicable specifications: different containers and covers have different sizes. First, determine the specifications of the paint bucket, paint bucket or lubricating oil bucket to be used, and then select the matching pneumatic capping machine.

2. Pressure and speed: according to the actual demand, select a pneumatic capping machine with sufficient pressure and appropriate speed. The output pressure of the capping machine should be able to ensure that the lid is firmly sealed on the container, and the working speed should also take into account the requirements of production efficiency.

3. Working principle: pneumatic capping machine uses pneumatic power to generate pressure to press the lid onto the container. The operation mode is simple. Just place the container on the machine and press the start button to complete the capping operation.

4. Material and compliance level: pneumatic capping machines are usually made of high-quality materials and made of materials that meet sanitary standards, such as 304 stainless steel, to ensure health and safety during use.

Pneumatic capping machine It can be used in many industries and products, such as food processing, pharmaceuticals, cosmetics, chemicals, etc. It is suitable for all kinds of capping operations with caps, such as paint buckets, paint buckets, lubricating oil buckets, etc.

With other automation equipment (such as Labeling machine )Combined use can improve the production efficiency of the factory. Through automatic gland operation, more efficient and safer work can be achieved. At the same time, it can also reduce the labor input, reduce the work intensity, and improve the automation level of the production line

Choose professional Pneumatic capping machine , which can provide convenient and efficient gland solutions for enterprises.