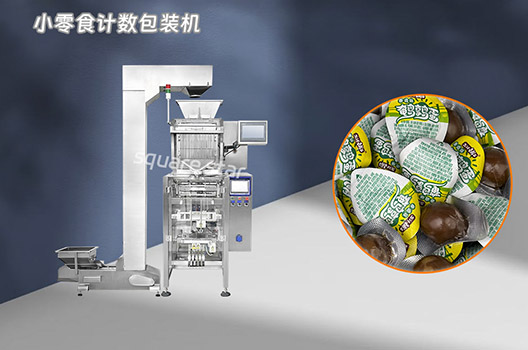

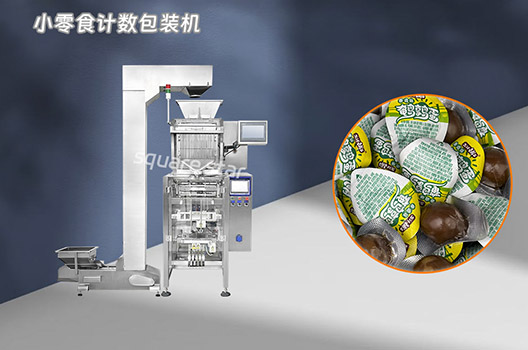

Leisure snacks and preserved eggs are a favorite snack for consumers, while Counting packaging machine It can help manufacturers accurately count and package leisure snacks such as braised eggs. Choosing a good counting packaging machine can improve production efficiency, reduce labor costs, and ensure product quality and safety.

In Select Counting packaging machine The following factors need to be considered:

1. Counting precision: the counting precision of counting packaging machine is very important. It is necessary to be able to accurately count each brine egg to ensure that the number of packages is consistent. Generally speaking, the counting accuracy shall be within ± 0.5%.

2. Adaptability: Different kinds of leisure snacks have different characteristics. The counting and packaging machine needs to be able to adapt to different shapes, sizes and materials of salted eggs. Therefore, it is very important to select a counting packaging machine with good compatibility.

3. Simple operation: the operation of the counting packaging machine should be simple and easy to understand, and the operator can start the operation without too much training. This improves productivity and reduces human error.

4. Convenient maintenance: the counting packaging machine shall be easy to maintain and clean to ensure its normal operation and sanitation.

5. Safety and hygiene: The counting packaging machine shall be made of food grade, safe and hygienic materials, such as medical 304 stainless steel. This can ensure that the product is not contaminated and meets the food hygiene standards.

Counting packaging machine The working principle of is mainly divided into the following steps:

1. Feeding and conveying: brine eggs are conveyed from upstream equipment (such as brine picker) to the feeding system of counting and packaging machine, usually through conveyor belt or vibrating plate.

2. Counting system: the counter packer counts the salted eggs according to the preset counting parameters. The counting system generally uses photoelectric sensors or vibrating rod sensors to count by detecting the position or quantity of the brine eggs.

3. Filling: After counting, the bittern egg will be automatically filled into the packaging bag, bottle or other containers. For different forms of leisure snacks, the counting packaging machine can be equipped with different filling systems, such as vacuum nozzles or filling tubes.

4. Packaging sealing: after the packaging bag or bottle is filled, the counting packaging machine will seal it to ensure the freshness and safety of the product.

Through these steps, Counting packaging machine It can automatically count and package the bittern eggs, improve production efficiency and reduce manual operation.