Shanghai Fangxing High Speed Counting Packaging Machine | Waterfall Granulator Through the unique visual recognition function, it has broken through the bottleneck of traditional photoelectric grain counting machine in counting grains. It can count all kinds of small parts, including medical devices, hardware parts, seeds, and all kinds of small particles.

Waterfall granulator can be configured with different packing machines, which can output different packing forms (bottled/boxed/bagged) counting packaging with error alarm, and waterfall granulator has automatic fault shutdown function. This machine is designed according to GMP standards. It integrates light, electricity and machinery, and is suitable for sealing and packaging of tablet, capsule counting and other granular packaging products in pharmaceutical, food and other industries.

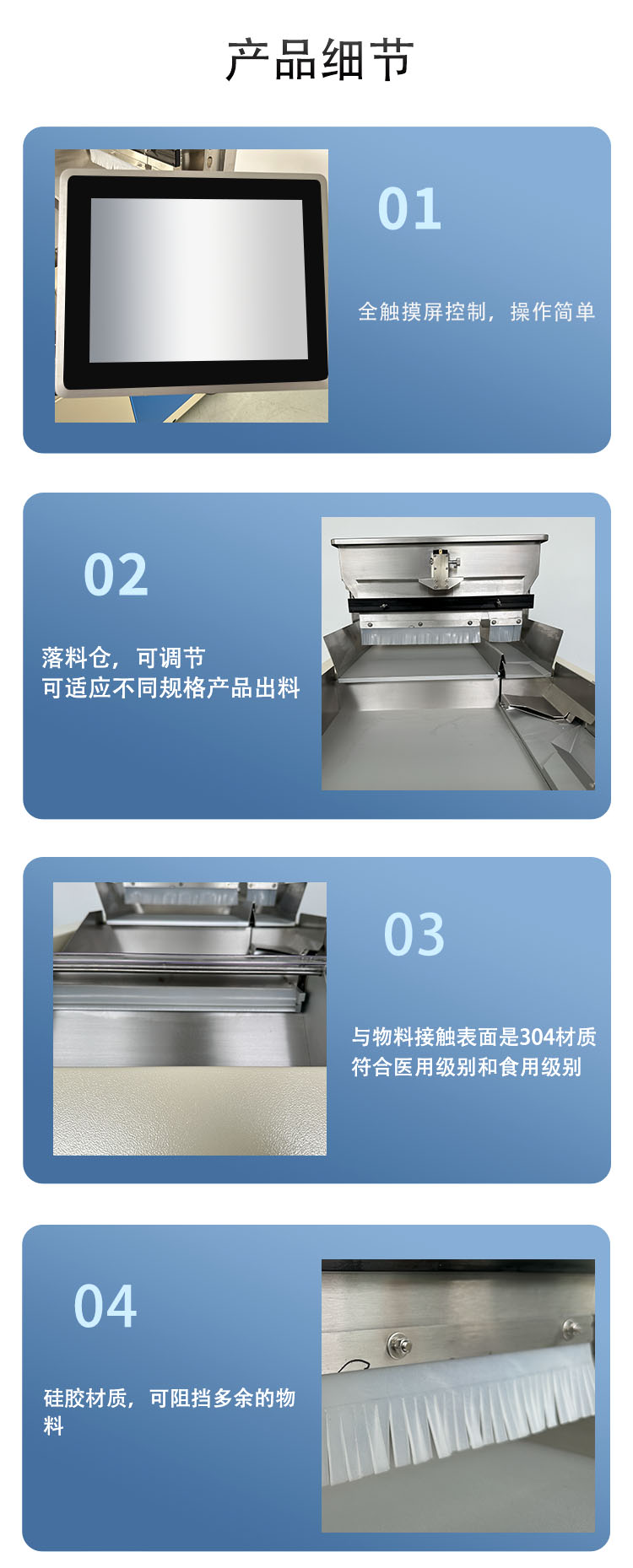

1. Single camera scanning recognition technology can quickly and accurately identify the falling attitude of materials through the attitude adjustment plate

The specific quantity of materials is suitable for objects of different sizes, not affected by dust, reliable, stable, convenient and practical.

2. Imported high-speed linear array CCD sensor with a resolution of 2048 and a scanning speed of 10000 per second

Times; Equipped with 6 million high-definition optical lens, 0.3mm particles can be identified, and the accuracy of counting particles is 100%, which greatly saves the time of counting particles.

3. Two channels adopt two-level control

The speed difference between the front and rear tracks and other mechanical structures make the material

It can pass in sequence, effectively improving the accuracy of several particles, and is suitable for medium and large particle materials with high accuracy requirements.

4. Two storage bins A and B are used. Bin A temporarily stores the materials passing through the main channel, reaches the set quantity, and enters into Material B

The bin is then accurately supplemented by the auxiliary channel, so that the main channel and the auxiliary channel are basically working at the same time

The counting efficiency improves the counting accuracy, and the performance is stable.

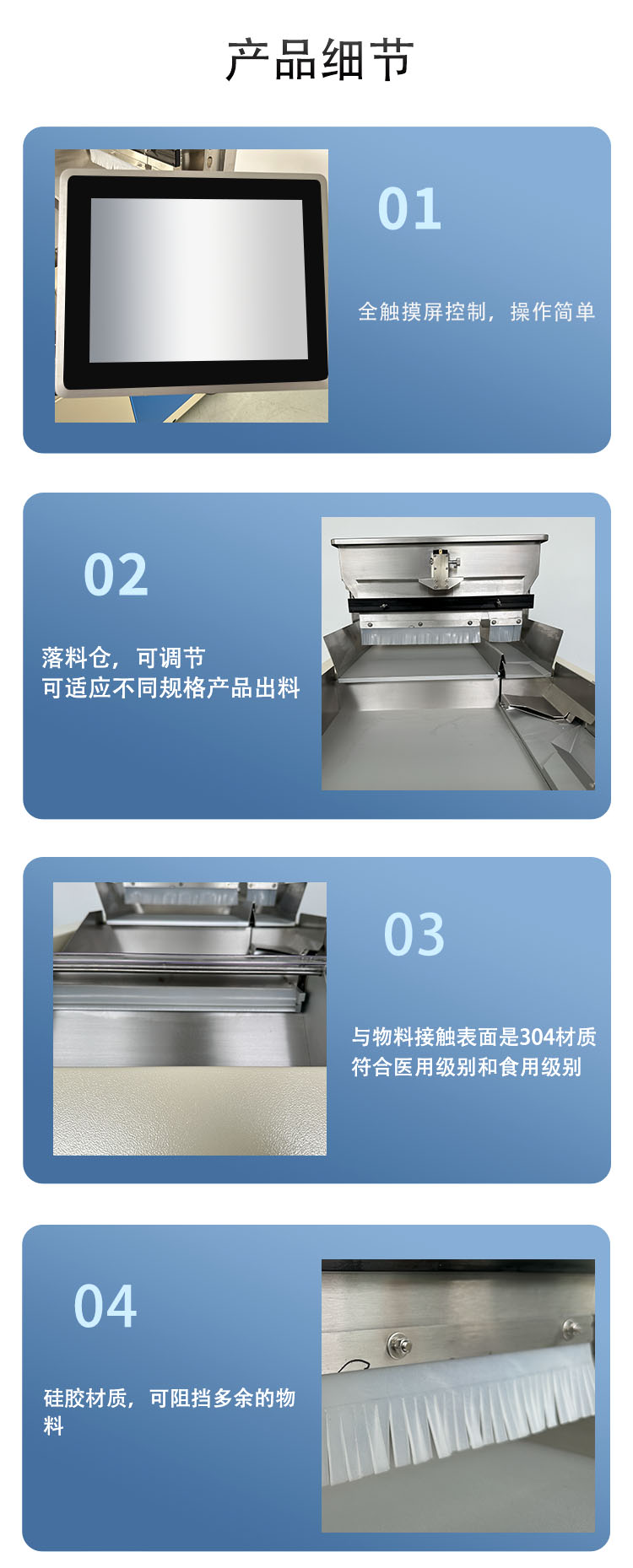

5. The touch industrial control screen is adopted, with friendly interface, simple and easy to understand, and easy to use.

6. All parameters are saved in the industrial computer, which theoretically supports the identification and control parameters of various materials, and can distinguish fragments and particles

At the same time, materials can be removed in small piles to avoid capacity waste.

7. The feeding mode supports multiple modes such as foot feeding, touch feeding, and automatic feeding.

8. Quick material change: One button quick cleaning function can quickly empty the remaining materials of the equipment

Set the material to be counted as the current one, and the replacement of several pieces of material can be completed within three minutes.

Fragments and fragments can be distinguished.

10. Intelligent detection and alarm function: foreign matter detection and alarm, material shortage detection and alarm, packaging machine abnormal alarm, and the machine is equipped with complete online detection and elimination devices.