Shanghai Fangxing DI-220 Desiccant feeder It is a supporting special equipment for all kinds of packaging machinery for Chinese and western medicine tablets, pills, capsules and other solid medicines bottled, boxed or bagged into solid desiccants. The desiccant feeder is used in the pharmaceutical industry, health products industry, food industry and other industries, and conforms to various GMP standards. The function of this machine is to automatically cut and fill the whole roll of bagged desiccant. Adopt perfect automatic program to control the filling of desiccant; The precise positioning of the cursor and the verification of the desiccant bag length determination system ensure the precise blanking of desiccant.

Shanghai Fangxing DI-220 desiccant feeder is mainly applicable to pharmaceutical, chemical, food and other industries. It is a special equipment to prevent the articles in the bottle from getting damp during transportation and storage. Machine stopper desiccant can avoid unnecessary pollution caused by manual stopper desiccant and improve labor productivity. Relevant supporting equipment includes Granulator , Capping machine , Labeling machine Aluminum foil sealing machine, bottle washing machine and other packaging machinery.

Product description:

1. The height of the discharge port can be adjusted, and the blanking valve is designed to be closest to the bottle mouth, so that the feeding is accurate and fast.

2. PLC is used to control frequency conversion speed regulation.

3. Compared with traditional desiccant feeding, the speed is increased by 100~200%

4. The desiccant is not inserted into the detection device, which increases the product qualification rate.

5. Add the function of automatic stop when opening the door to effectively protect the personal safety of operators.

6. The pneumatic bottle clamping mechanism is adopted to make the machine work stably and reliably.

7. Automatic fault diagnosis, real-time audible and visual alarm and display system.

8. Comply with GMP specifications.

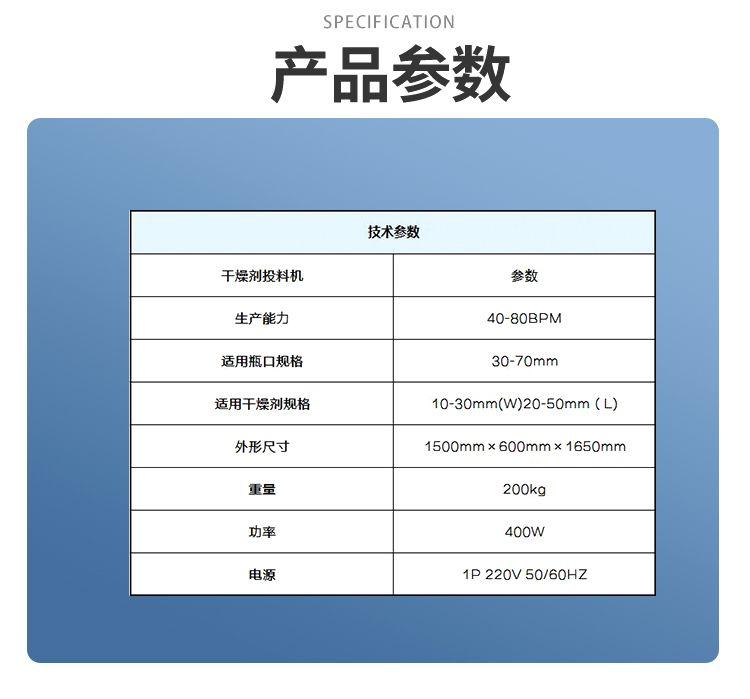

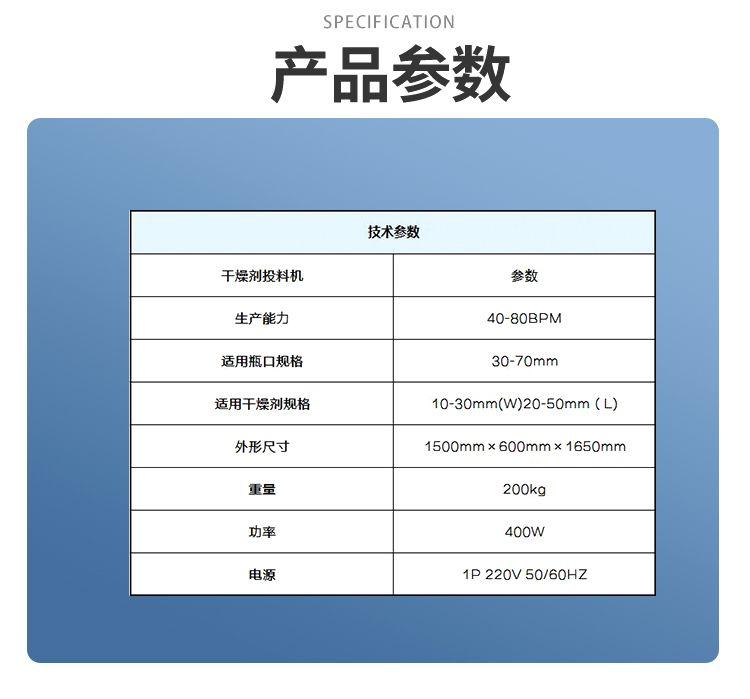

Production speed (bottle/minute) 100~120, voltage V/HZ210/50, power Kw0.55, overall dimension mm1000 × 490 × 1400, weight Kg230