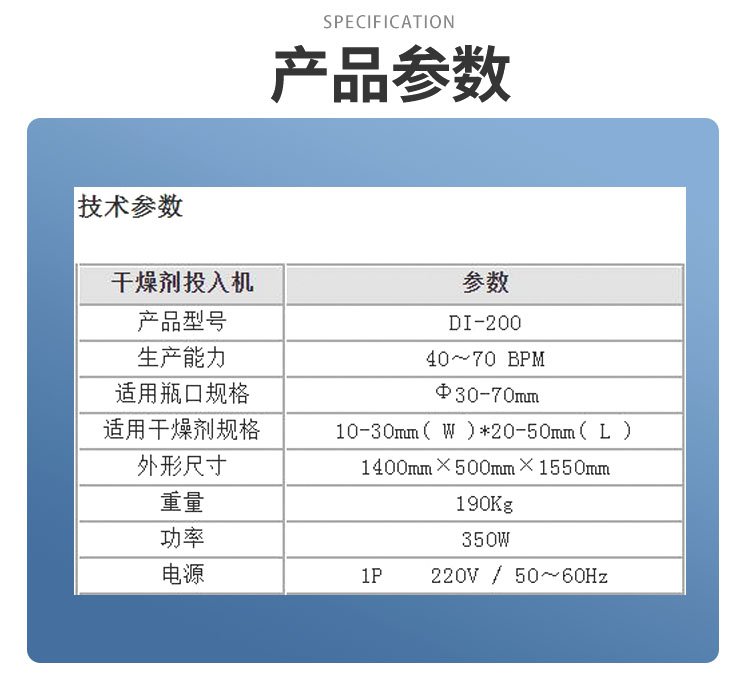

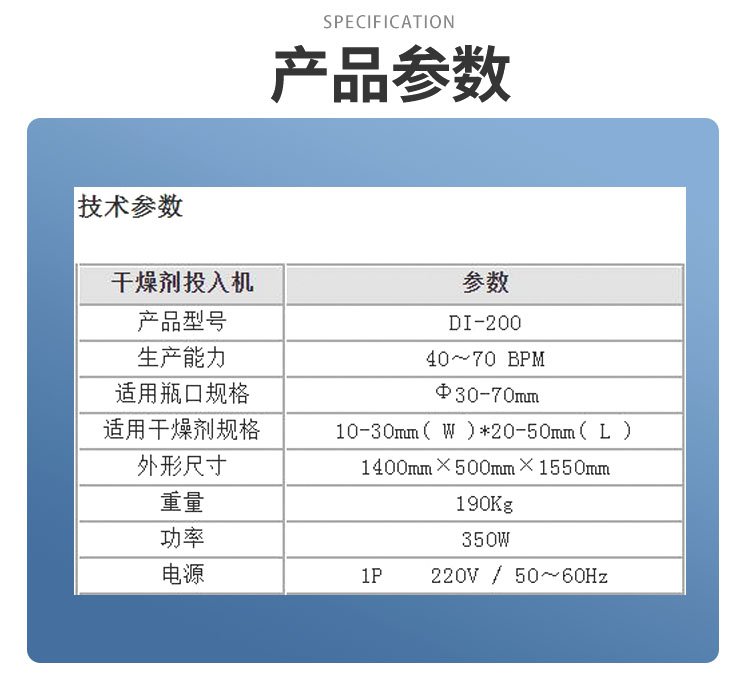

Brief introduction of desiccant feeder equipment

DI-200 The T-shaped strip desiccant feeder is a special equipment for the bottle, box or bag loading of Chinese and western medicine tablets, pills, capsules and other solid medicines into solid desiccants. It is used in the pharmaceutical industry, health care products industry, food industry and other industries, and conforms to various GMP standards. The function of this machine is to automatically cut and fill the whole roll of bagged desiccant. Adopt perfect automatic program to control the filling of desiccant; Through precise positioning of the cursor and verification of the desiccant bag length determination system, the desiccant will not be cut.

This machine is mainly applicable to medicine, chemical industry, food and other industries. It is a special equipment to prevent the articles in the bottle from getting damp during transportation and storage. The machine stopper desiccant can avoid unnecessary pollution caused by manual stopper desiccant, and improve labor productivity.

Desiccant feeder Product features

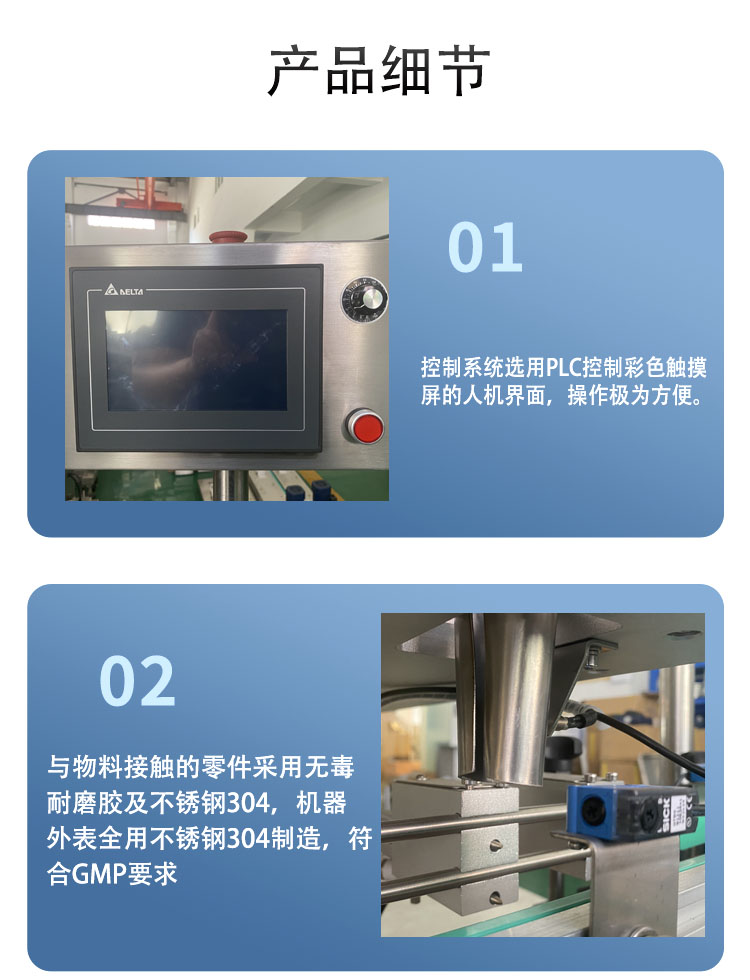

² The operation is simple and convenient. Users can freely set the production capacity and select bottles of different specifications within the design range of the machine; Simple switching between different specifications and convenient adjustment;

² It is flexible in application, has the function of automatic bottle separation, can be produced on a single machine, can also be used with or embedded in the assembly line, and can be intelligently controlled with the previous and next processes, with good coordination, no need for special personnel to operate, and saves labor;

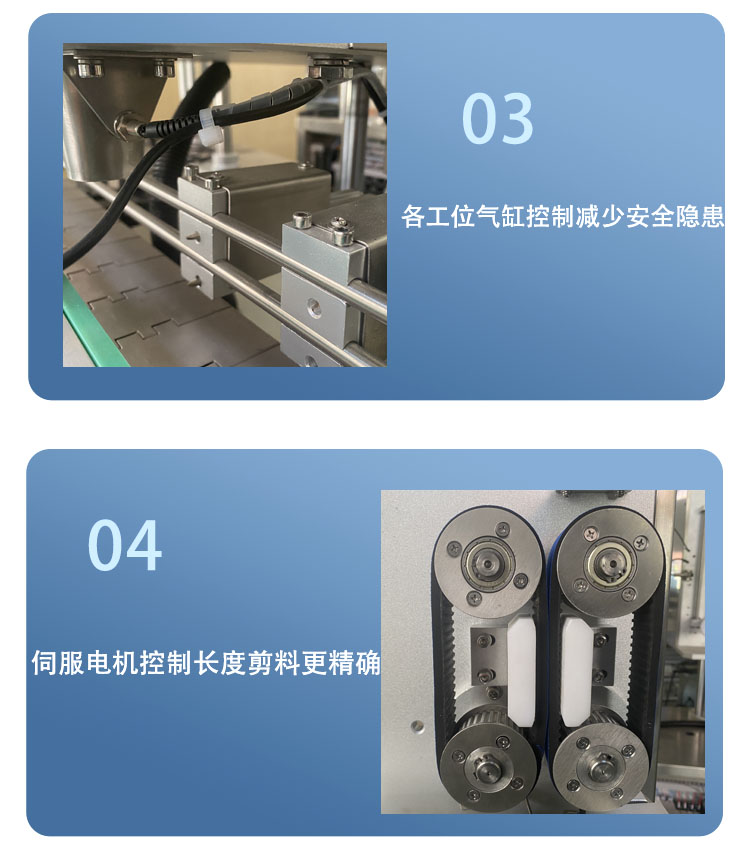

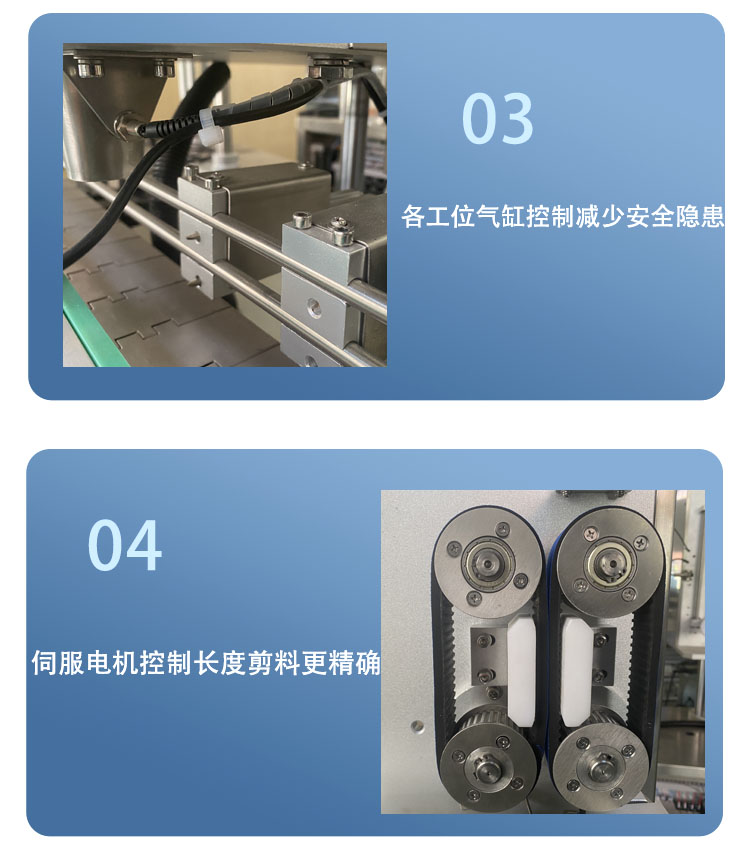

² The cutting knife is controlled by air cylinder, the knife edge is durable and not easy to wear, and the cutting action is neat to ensure the integrity of the drying bag;

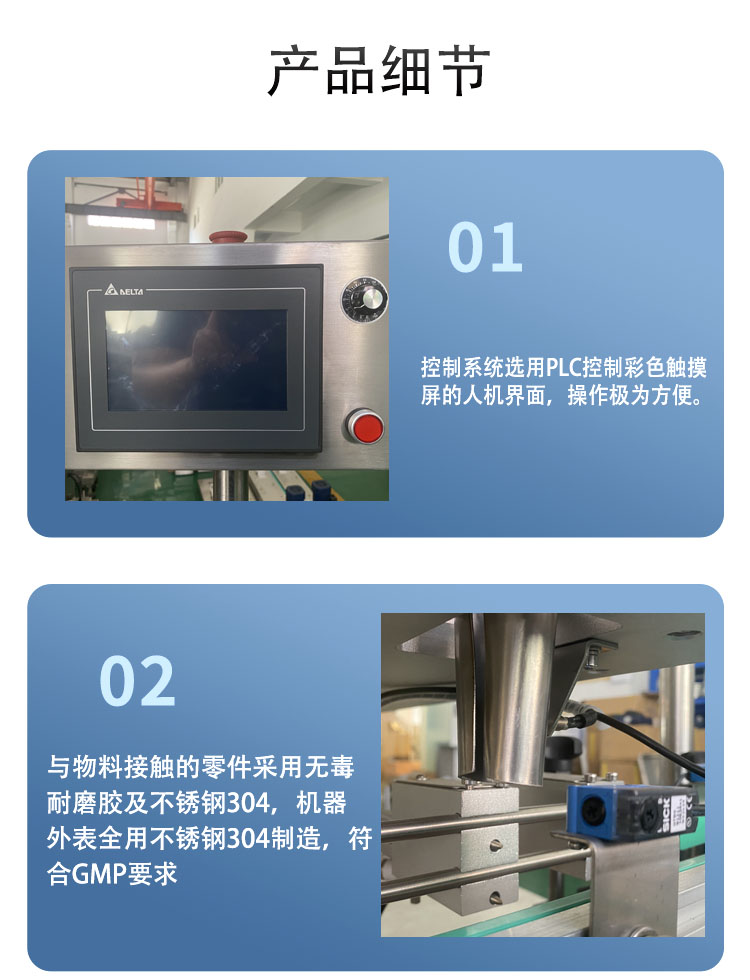

² PLC Control, Chinese and English dialogue control panel, can store ten groups of data, easy to adjust, and the operator can easily start;

² The dry pellet packing strip is driven and transported by a stepping motor, and the feeding is stable and smooth. It is equipped with an optical electric eye for precise sensing, and the dry pellet packing is positioned accurately, which can effectively prevent the drying bag from cutting and polluting the product;

² Optional data network interface for data storage and reading management.

² Complete equipment supporting data (including equipment structure, principle of desiccant feeder, Desiccant feeder Operation video, Desiccant feeder Maintenance, Desiccant feeder Maintenance, upgrading and other instructions), to provide adequate guarantee for the normal operation of the equipment.