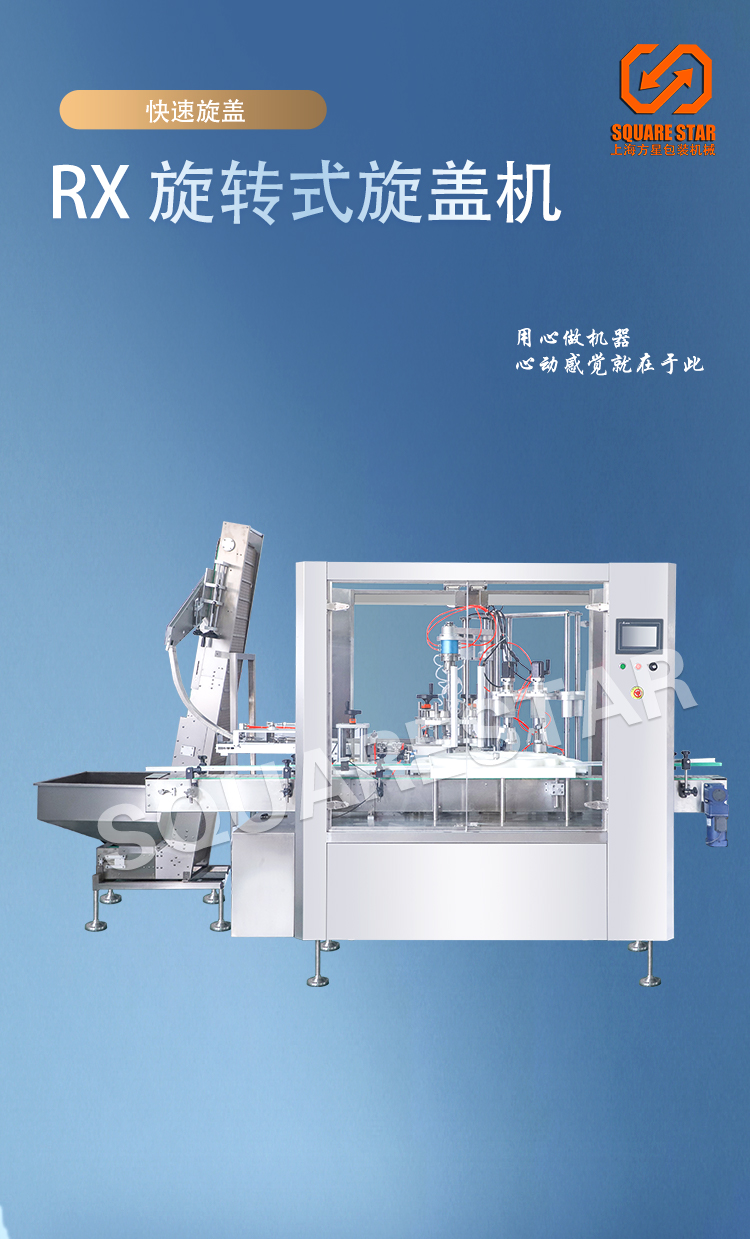

Equipment Introduction

RX series Capping machine It is an automatic capping machine specially designed for the bottling production lines of medicine and health products, food, daily chemicals and other industries. The star disk structure is adopted, which integrates lid management, bottle entry, cap rotation and bottle exit, and can accurately position and cap rotation for each bottle. There is no damage to the bottle or the cap during the capping process, and it is suitable for plastic caps of various specifications. The constant torque capping mechanism can ensure that the rotation of each capping head will stop automatically when the tightening force reaches a certain torque, and the torque can be easily adjusted. The whole machine adopts PLC control and touch human-machine interface, which is convenient and intuitive to operate.

This machine has the advantages of fast capping speed, high efficiency, smooth operation and wide application range. It can be used together with various bottling lines to meet the requirements of GMP and FDA.

Product features

Frequency conversion speed regulation of the whole machine, PLC Control and touch screen display are clear and easy to understand;

Constant torque capping head ensures that the capping head will stop rotating after the lid meets the tightness requirements, which is suitable for products with high requirements for tightness;

Photoelectric sensor detection, suspension of operation due to bottle shortage or bottle blockage, and automatic operation after recovery;

The cap lock head can be replaced to meet different cap lock and capping requirements;

The structure is tight, and all parts such as electrical control are sealed to prevent the materials from affecting the service life of electrical components;

The embedded buckle structure is adopted, which is easy to disassemble, clean, use and maintain;

In the normal production process, there is no need for special personnel to watch, and various automatic protection devices are equipped;

The body shell is made of stainless steel three hundred and four Material manufacturing, in accordance with GMP requirement;

The equipment operation area is equipped with a safety cover to provide more safety guarantee for operators;

Complete equipment supporting data ( Including equipment structure, principle, operation, maintenance, repair, upgrade and other information ) , providing sufficient guarantee for the normal operation of equipment;

Optional inspection mechanism for defective screw cap and aluminum foil free;

Optional data network interface for data storage and reading management.