The round bottle labeling machine is applicable to the labeling of various cylindrical containers. It adopts a special high-speed and stable labeling device to minimize the up and down displacement of labels during high-speed movement, thus ensuring the precision of labeling. The highly sensitive label photoelectric and intelligent length confirmation system ensure the consistency of the label length. This machine is equipped with a multiple detection system, which can effectively control the normal operation of the whole system. No bottle or bottle blockage will automatically stop the machine, and it will automatically run after recovery. The specification change is simple and convenient.

This labeling system can also be equipped with a series of detection systems, such as the clarity detection of printed characters, barcode, two-dimensional code detection, labeling confirmation, etc. Optional data network interface for data storage and reading management.

Features of round bottle labeling machine

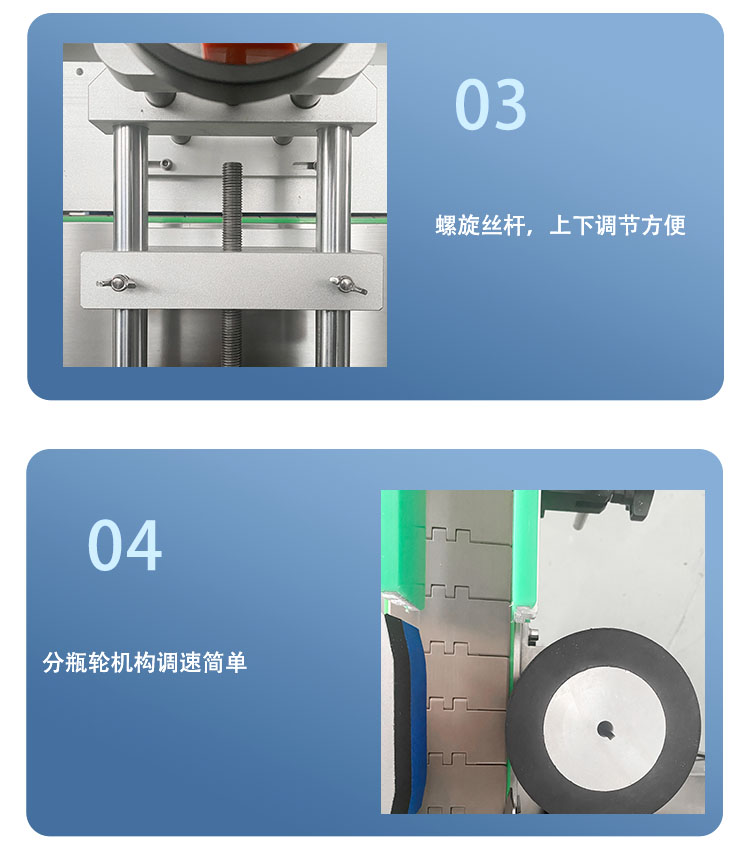

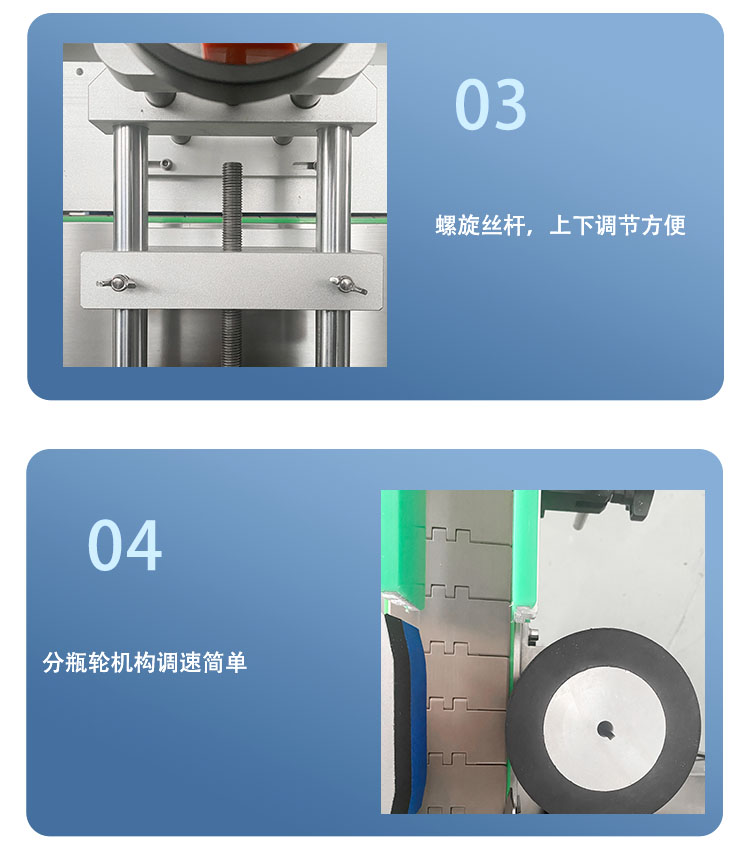

Wide application range of labeling, simple switching of labeling between bottles, and convenient adjustment;

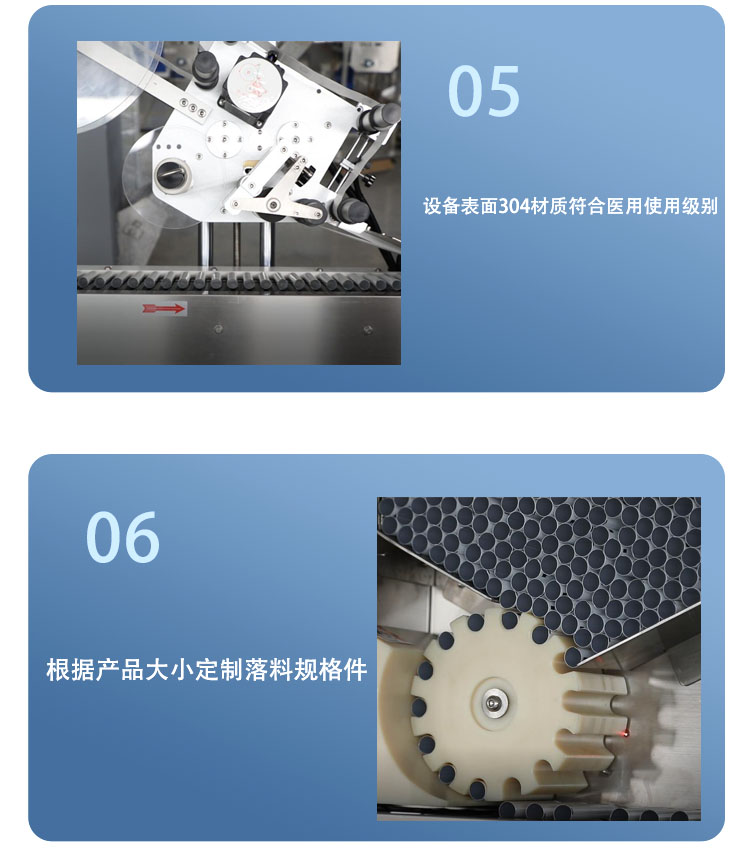

The labeling precision is high, and the deviation correction mechanism is adopted for the tape winding, which has good stability, and the labeling is flat, wrinkle free, and bubble free;

The labeling quality is excellent. The elastic and compressive label covering belt is used to make the labeling smooth and wrinkle free, so as to improve the packaging quality;

The labeling speed, conveying speed and bottle separating speed can realize stepless speed regulation, which is convenient for production personnel to adjust according to actual needs;

Flexible application, bottle standing labeling, automatic bottle separation; It can be produced by single machine or by assembly line;

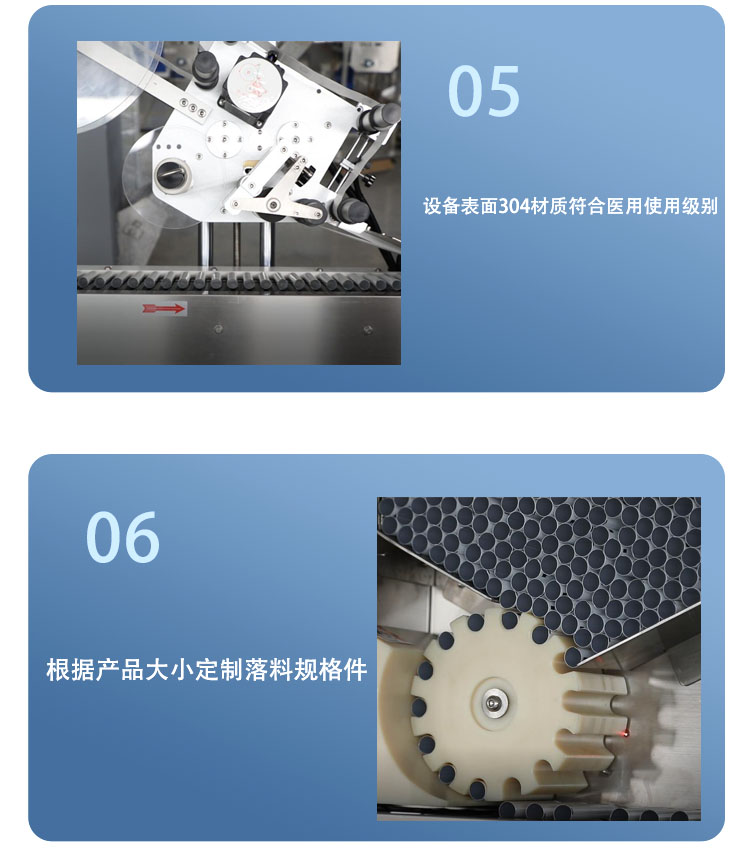

It is firm and durable. Three bar adjustment mechanism is adopted to make full use of the stability of triangle. The whole machine is firm and durable. It is made of stainless steel and high aluminum alloy, meeting GMP production requirements.

The structural combination of the mechanical adjustment part and the ingenious design of the label winding make it easy to fine tune the degree of freedom of the labeling position (it can be completely fixed after adjustment), making the conversion between different products and the label winding simple and time-saving;

The main materials of the equipment are stainless steel and high aluminum alloy, and the overall structure is firm and beautiful;

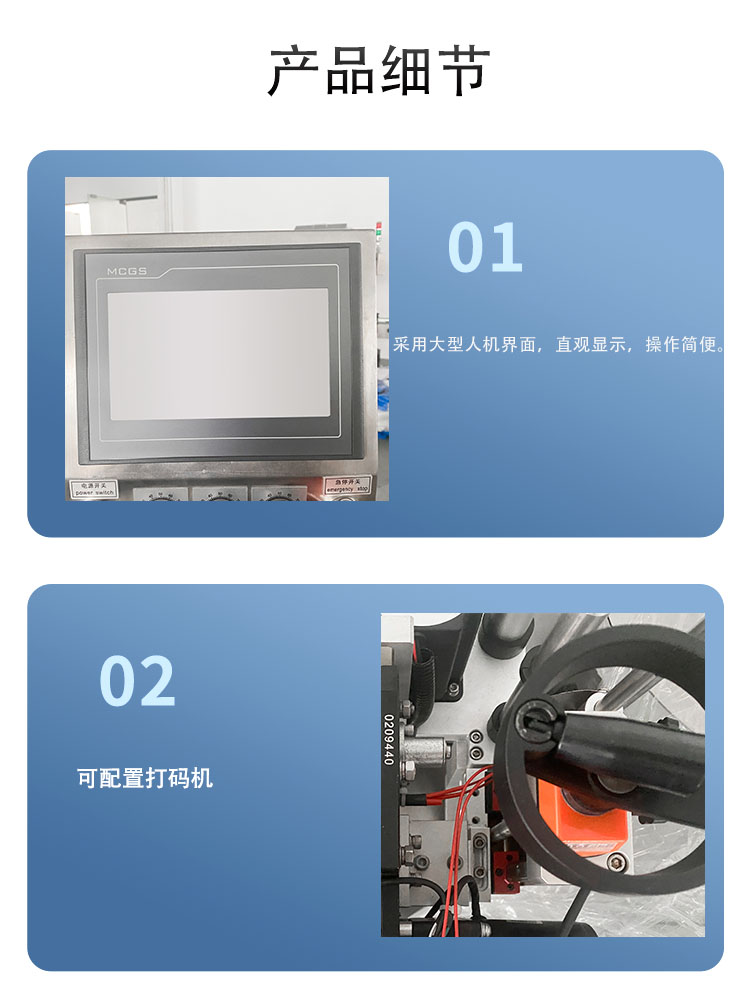

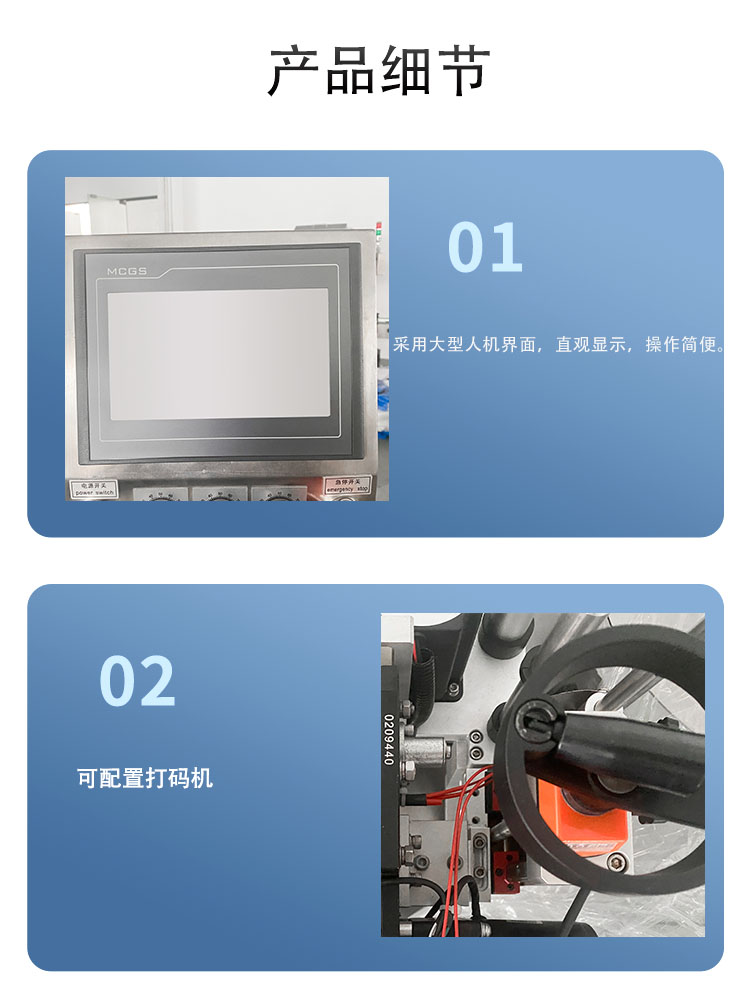

It is controlled by the world famous brand PLC+touch screen+motor+sensor and other electronic control systems, with high safety factor, full Chinese annotation of human-computer interaction interface, perfect fault prompt function and operation teaching function; Easy to use and maintain;

It has the functions of no matter what, no label, no label automatic correction and automatic detection;

It has fault alarm function, production counting function, production number setting prompt function, parameter setting protection function (parameter setting is managed by authority);

Complete equipment supporting materials (including equipment structure, principle, operation, maintenance, repair, upgrade and other explanatory materials) to provide adequate guarantee for normal operation of equipment;

Optional functions: ① Hot coding/code spraying function ② Automatic feeding function (considering the product) ③ Automatic receiving function (considering the product) ④ Add labeling device ⑤ Circumferential positioning labeling function ⑥ Other functions (customized according to customer requirements).