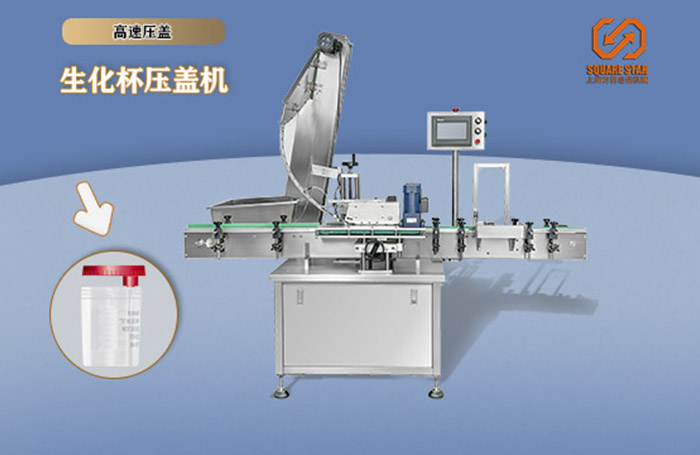

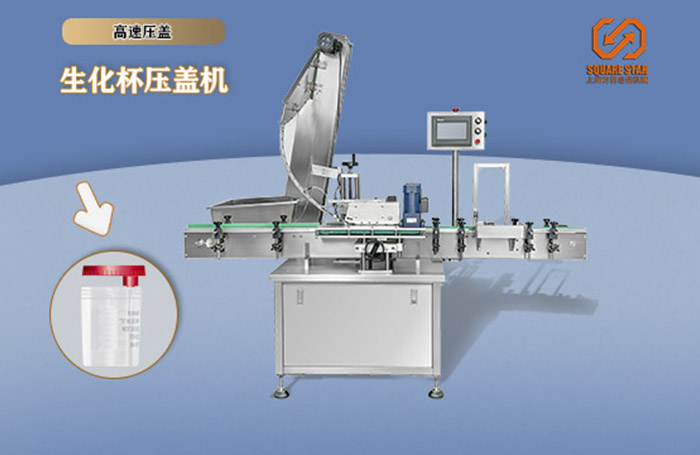

GX-200A lifting Capping machine It is different from the intermittent capping machine in the past and overcomes the shortcomings of the intermittent capping machine, such as slow capping speed, loose capping and small scope of application. In the design of this machine, new processes such as linear bottle feeding, automatic cap dropping, and uninterrupted capping are adopted, and the most advanced lifting cap dropping device in the industry is used in the design of cap dropping, which avoids the noise of oscillating cap dropping and greatly improves the output.

Features of capping machine

The whole machine adopts a touch screen with full Chinese interface, and the operation display is clear and easy to understand;

The frequency conversion speed regulation of the gland belt ensures the synchronous consistency with the conveying speed;

Stepped lifting belt is adopted for the upper cap, which makes the cap feeding fast and low noise;

The cap dropping structure has the function of automatic removal of the reverse cap (in addition to the self weight force of the cap, the air blowing method) to ensure that the cap can enter the rail smoothly without blocking the material;

The slope type gland belt gradually pressurizes the belt; First correct and then press tightly to ensure that the bottle cap is correct;

Automatic capping and capping, reducing labor intensity of workers;

The fuselage shell is made of stainless steel 304 material, meeting GMP requirements;

Complete equipment supporting information (including equipment structure, principle, operation, maintenance, repair, upgrade and other explanatory information), to provide sufficient guarantee for the normal operation of the capping machine;

It can be equipped with defective gland products and no aluminum foil detection and rejection mechanism;

The capping machine can be equipped with data network interface for data storage and reading management.