Equipment Introduction

This machine is widely used in the medicine, electronics, cosmetics, culture and education industries for labeling slender cylindrical objects (such as test tubes, vials, pens, lipsticks, solid glue, etc.) with circular and semi circular edges. Horizontal transmission and horizontal labeling are adopted to increase stability and improve labeling efficiency. Perimeter labeling of

This labeling system can also be equipped with a series of detection systems, such as the clarity detection of printed characters, barcode, two-dimensional code detection, labeling confirmation, etc. Optional data network interface for data storage and reading management.

Product features

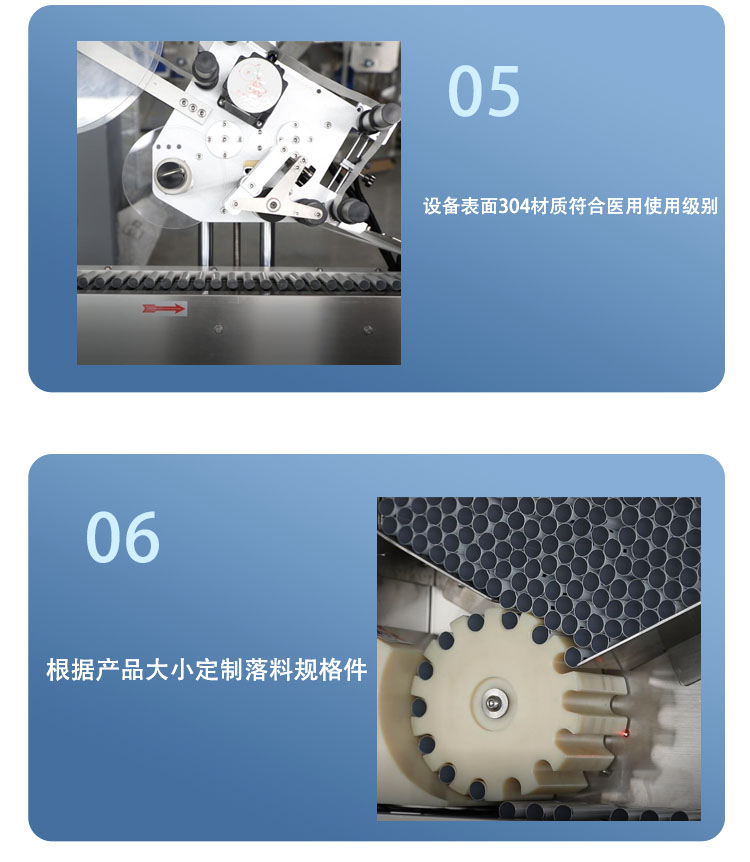

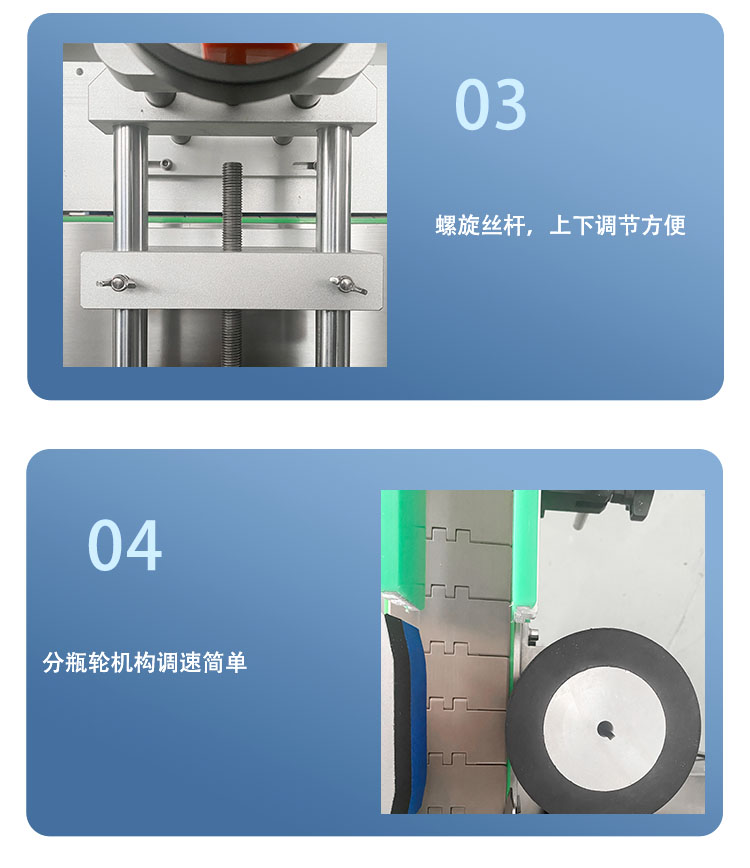

It is suitable for labeling round or half round slender objects such as oral liquid, small battery, penicillin bottle, etc., with convenient adjustment;

The side horizontal roller conveying mechanism is adopted, the conveying chain is inclined, the bottles are automatically guided, and the conveying and labeling are stable.

The labeling quality is excellent, and the tape detour correction technology is adopted, so that the head and tail of the label are aligned with each other in a high degree; Rubbing and rolling type label covering, the labeling is flat, without wrinkles and bubbles, and the packaging quality is improved;

The application of flexible bottle separation technology and flexible labeling technology makes the bottle separation and labeling smooth and the bottle breaking rate low;

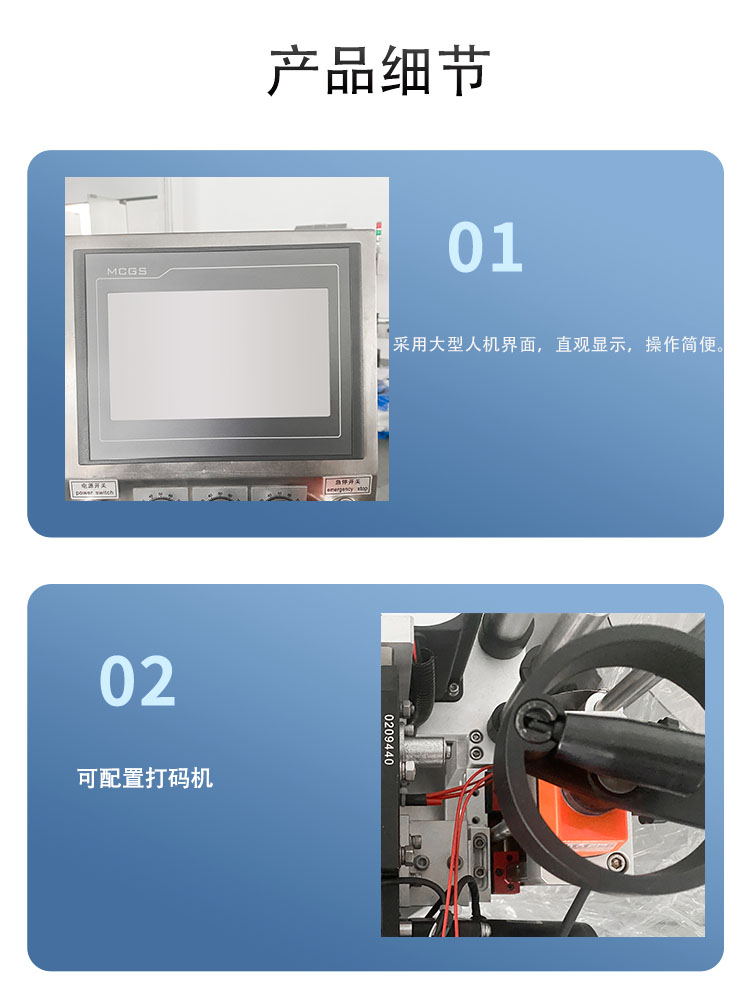

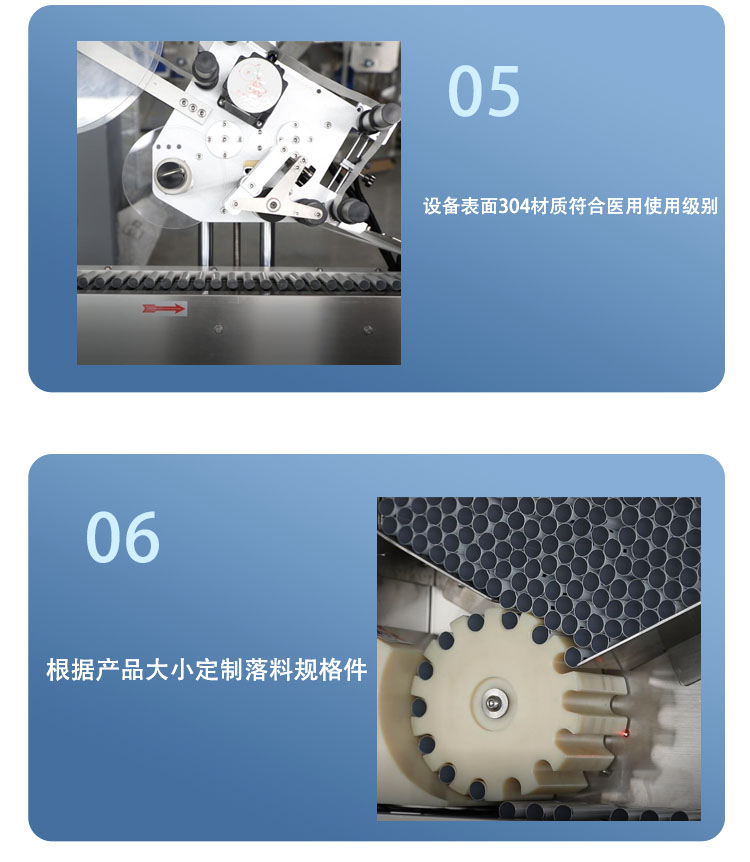

Dial type blanking, enlarged silo design, fast and convenient feeding;

The labeling speed, conveying speed and bottle separating speed can realize stepless speed regulation, which is convenient for production personnel to adjust according to actual needs;

It is firm and durable. Three bar adjustment mechanism is adopted to make full use of the stability of triangle. The whole machine is firm and durable. It is made of stainless steel and high aluminum alloy, meeting GMP production requirements.

The structural combination of the mechanical adjustment part and the ingenious design of the label winding make it easy to fine tune the degree of freedom of the labeling position (it can be completely fixed after adjustment), making the conversion between different products and the label winding simple and time-saving;

The main materials of the equipment are stainless steel and high aluminum alloy, and the overall structure is firm and beautiful;

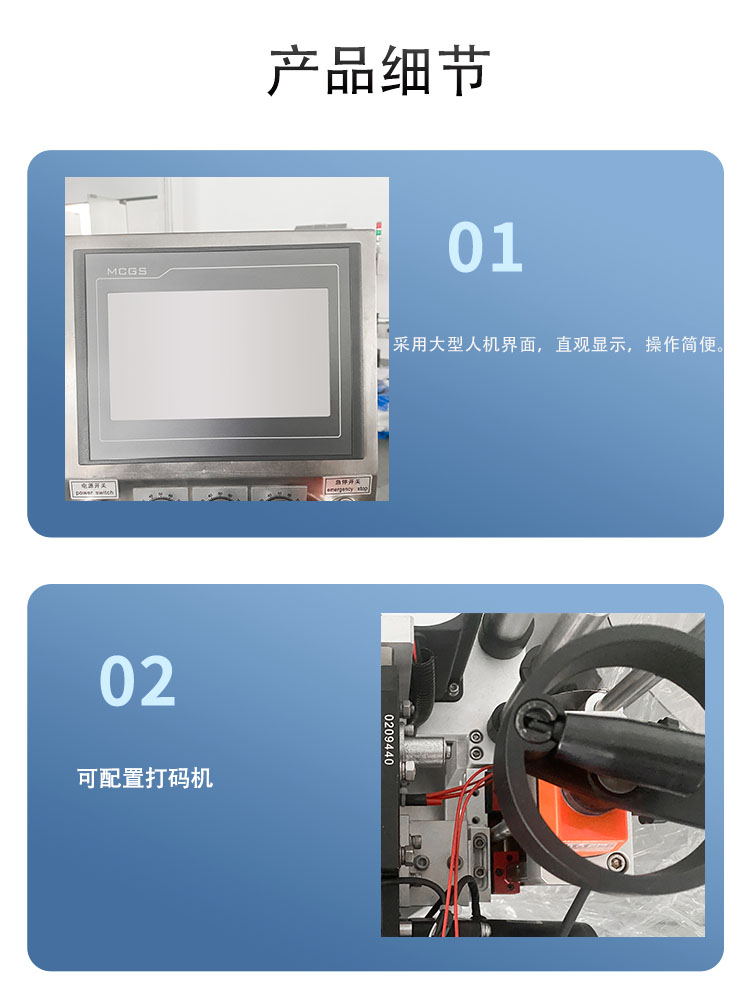

The mature brand PLC+touch screen+stepper motor+sensor electronic control system is used for control, with high safety factor, full Chinese annotation of human-computer interface, and perfect fault prompt function and operation teaching function; Easy to use and maintain;

Complete equipment supporting materials (including equipment structure, principle, operation, maintenance, repair, upgrade and other explanatory materials) to provide adequate guarantee for the normal operation of equipment;

It has the functions of no matter what, no label, no label automatic correction and automatic detection;

It has fault alarm function, production counting function, power saving function (when there is no production within the set time, the equipment automatically turns to the power saving standby state), production number setting prompt function, parameter setting protection function (parameter setting is managed by authority);

Complete equipment supporting materials (including equipment structure, principle, operation, maintenance, repair, upgrade and other explanatory materials) to provide adequate guarantee for the normal operation of equipment;

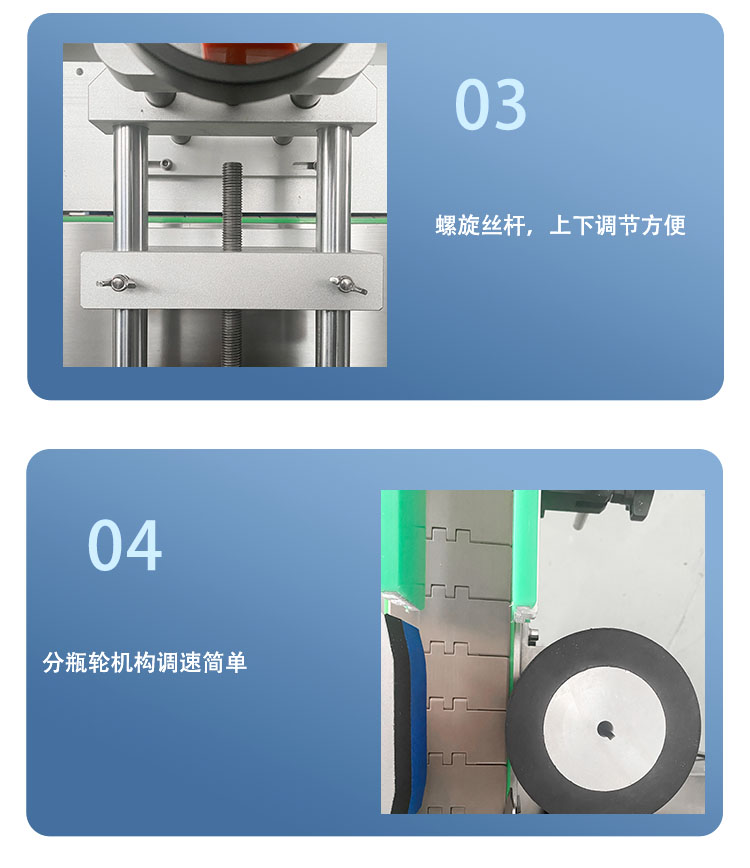

Optional functions: ① Hot coding/inkjet function ② Automatic feeding function (considering the product) ③ Automatic receiving function (considering the product) ④ Add labeling device ⑤ Other functions (customized according to customer requirements).

More pictures