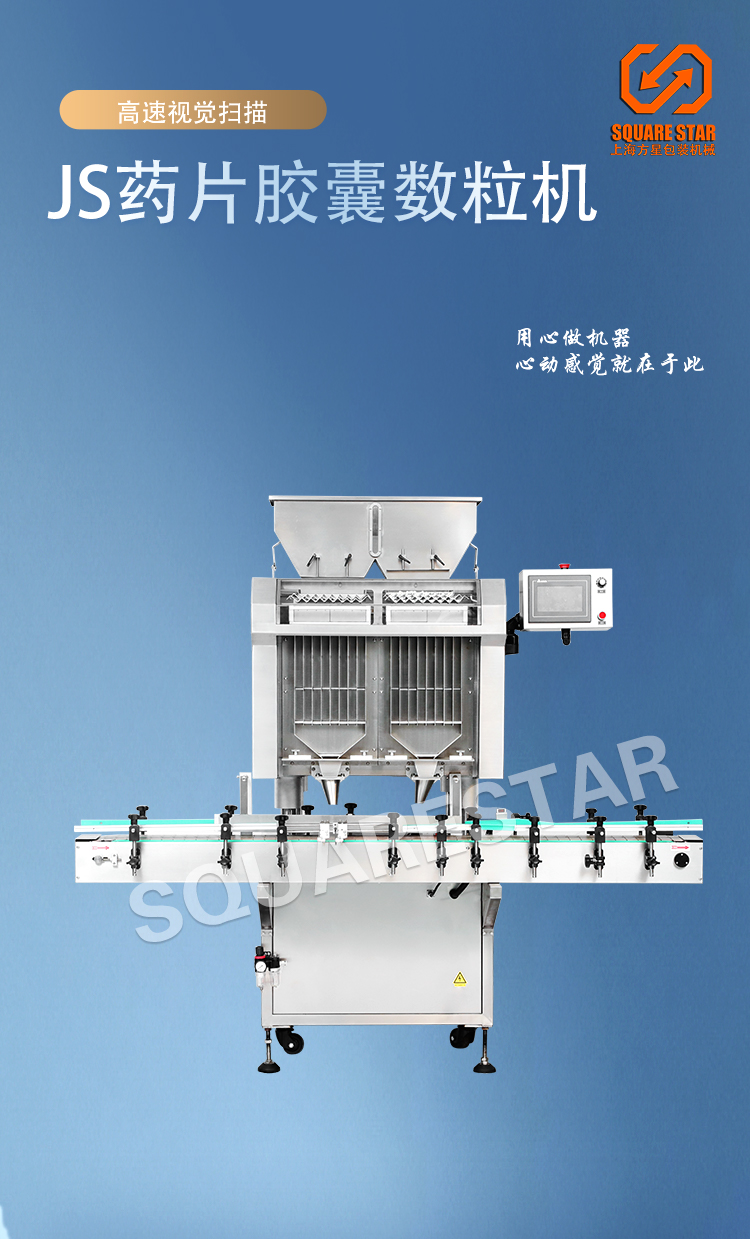

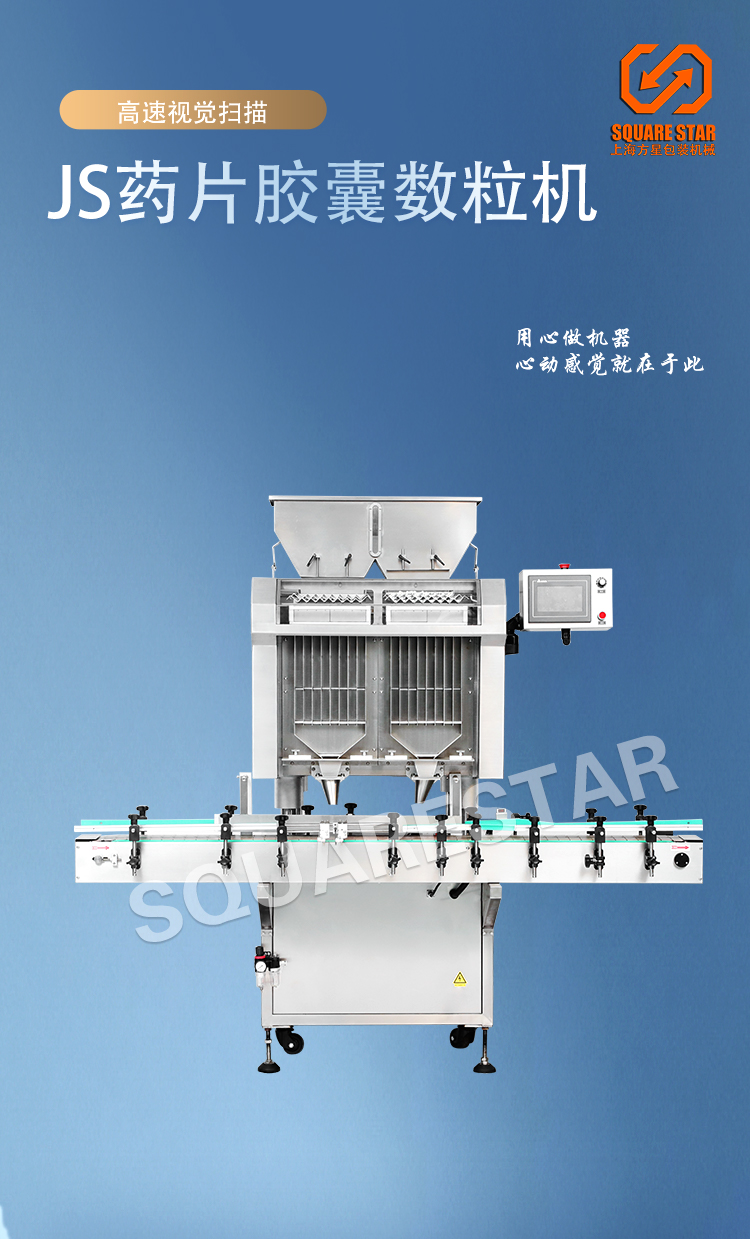

Equipment Introduction

Shanghai Fangxing JS series laser fully automatic Granulator Advanced European and American technologies are used to scan high-speed moving objects with high-speed lasers at a speed of up to 10000 frames/second, so as to obtain the projection map of the moving track of the object product. The real-time computing chip is supplemented by highly optimized visual algorithm to calculate and count the amount. Then, accurate counting and sub packaging are realized through synchronous control module.

The JS series automatic granulator has exquisite appearance, beautiful appearance and convenient maintenance. It is widely used in the counting and filling of solid preparations in pharmaceutical, health care products, food, pesticide, chemical, hardware and other industries. Can be used as: tablet Granulator , Candy Granulator , capsule Granulator , Seed Granulator Screw nut counting machine, plastic small parts Granulator Etc. JS series laser automatic counting machine can be used as a single machine, and can also form a complete bottling production line with other bottling equipment produced by our company.

The basic models of the JS series laser automatic grain counting machine are JS-8, JS-12, JS-16, JS-24, and JS-32 to meet the requirements of different grain counting capacities.

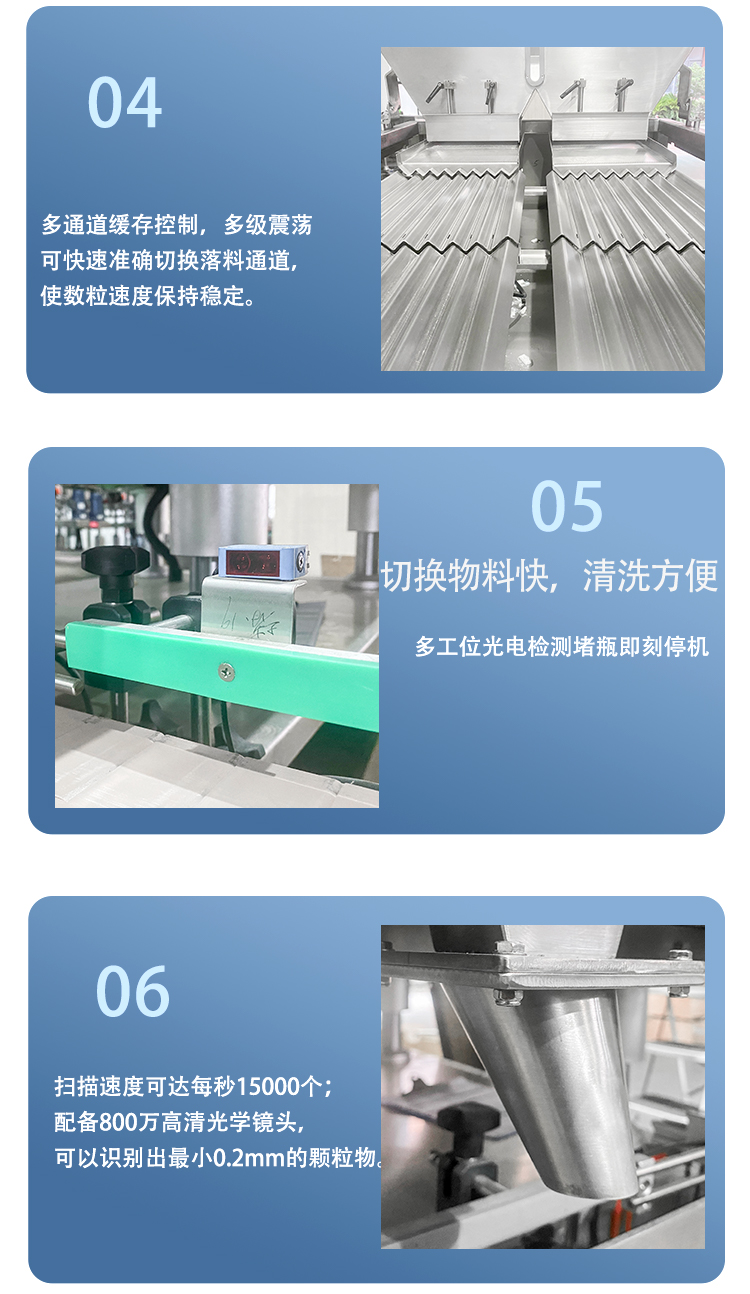

JS series laser automatic counting machine The machine can be used for a wide range of applications. The same equipment can pack several pieces of products with different specifications. It is easy to switch between different specifications and adjust them;

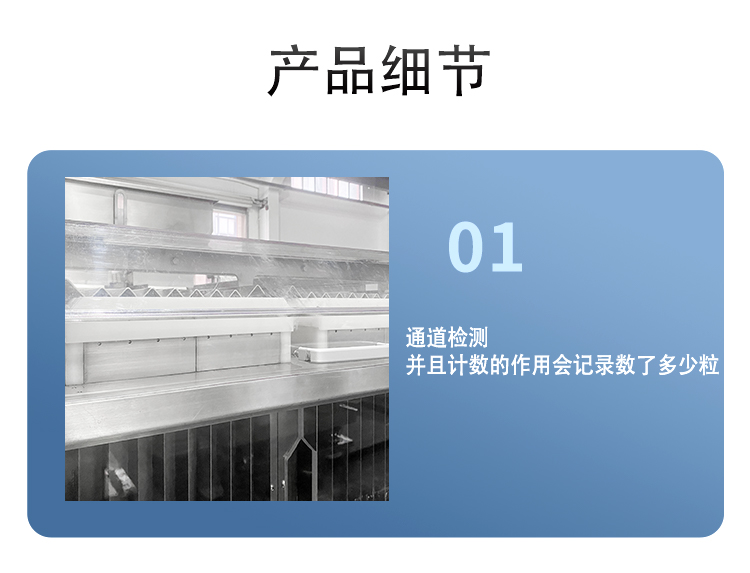

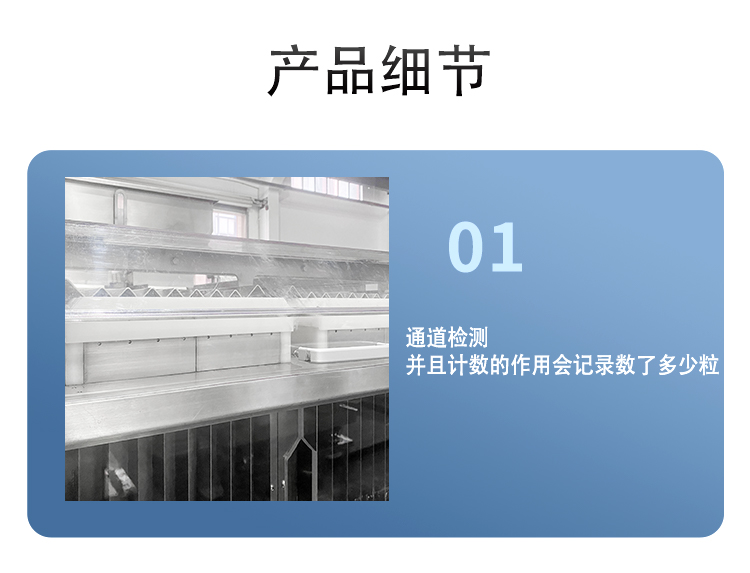

High speed vision particle counting technology developed independently is adopted to realize multi-channel synchronous recognition, with strong compatibility;

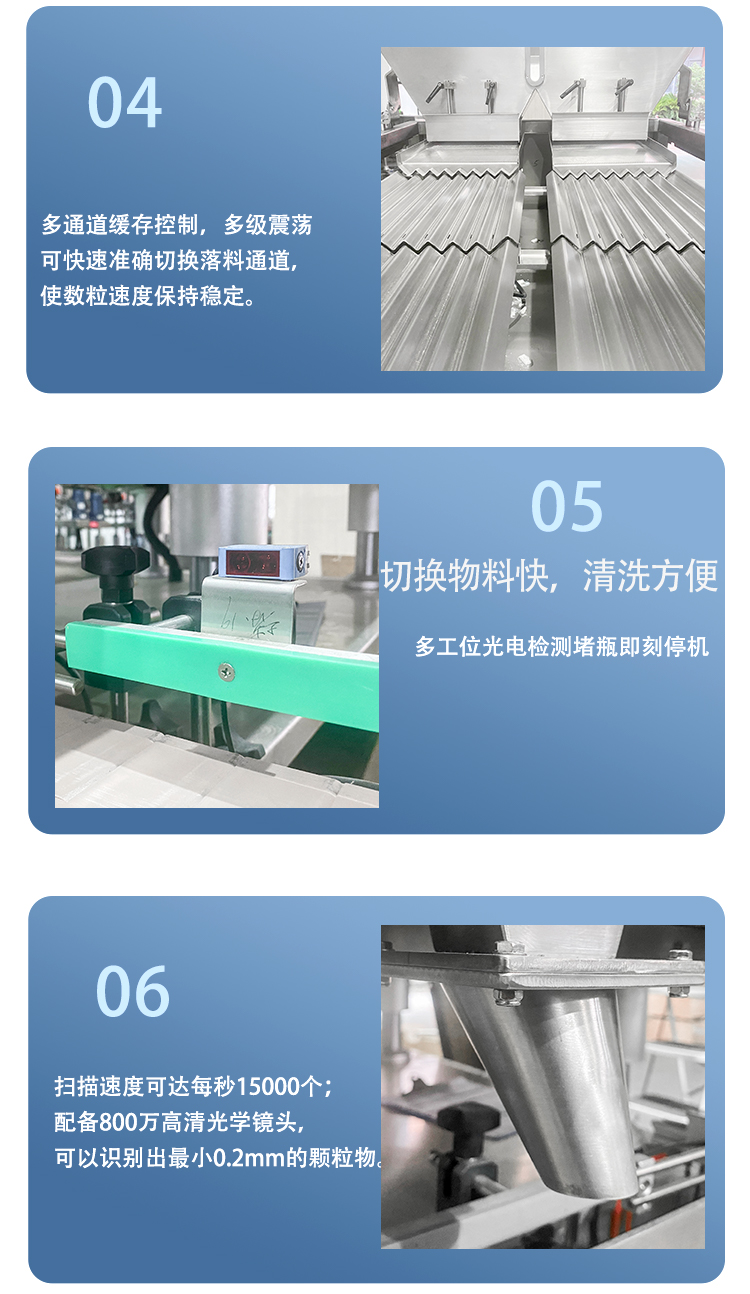

The imported high-speed linear array CCD sensor is adopted, with the resolution up to 2048 and the scanning speed up to 10000 times per second;

Equipped with 6 million high-definition optical lens, 0.3mm particles can be recognized in min.

JS series laser automatic counting machine The camera light control room is completely isolated from the material channel to reduce the impact of dust on the camera and light source, thus ensuring the high accuracy and speed of the equipment.

The industrial touch control screen is adopted, with friendly interface, simple and easy to understand, and easy to use. All parameters are saved in the work;

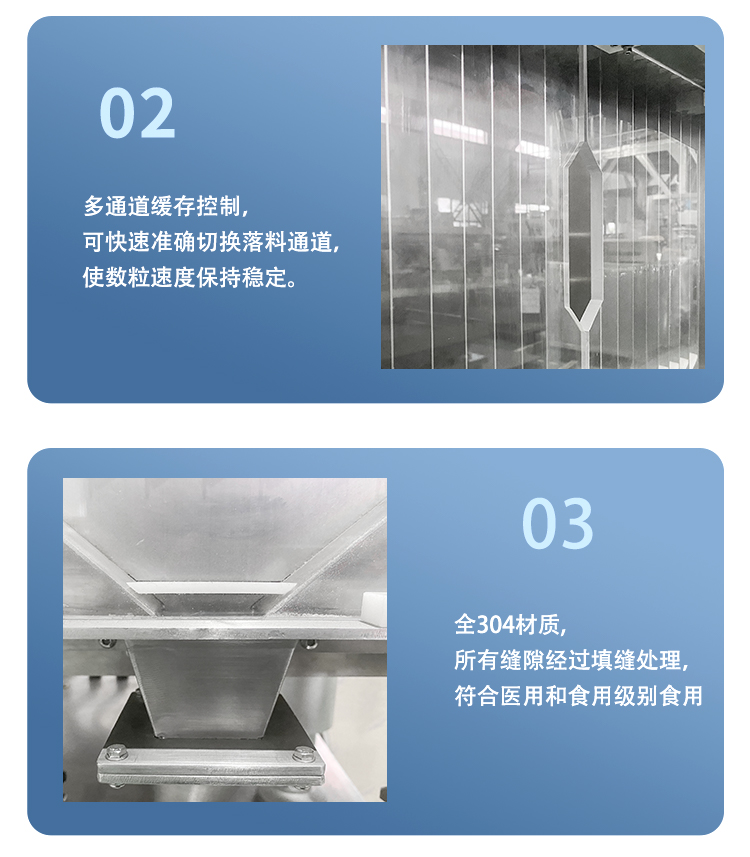

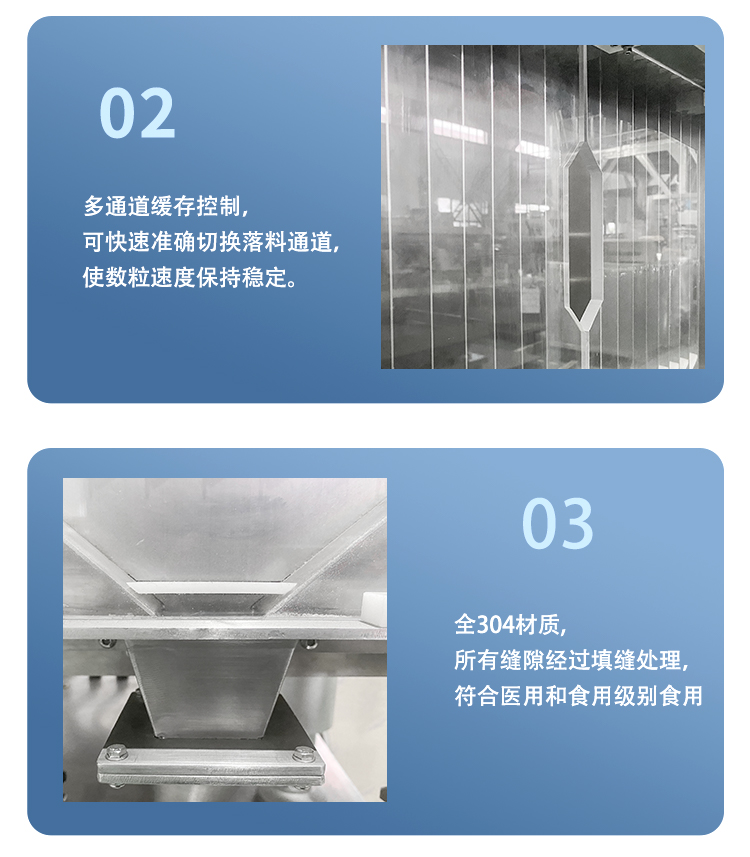

Three levels of vibration feeding are adopted for feeding, and each level can be adjusted separately, so that the material can travel faster and the posture is more uniform and smooth;

JS series laser automatic counting machine Stainless steel and non-toxic, chemically stable food grade non-metallic materials are used on the surface, which is easy to clean and free of dead corners;

It is equipped with bottle shortage and bottle blockage detection photoelectric device, which can effectively control the normal operation of the whole system. If there is no bottle or bottle blockage, it will automatically stop and automatically operate after recovery;

JS series laser automatic counting machine The independent setting mode of subcontracting and general contracting is adopted to effectively reduce the silo volume and improve equipment compatibility and freedom;

The feeding mode supports multiple modes such as foot feeding, touch feeding, and automatic feeding;

Quick material change: one button quick cleaning function can quickly empty the remaining materials of the equipment. After cleaning, just set the materials to be counted as current to complete the replacement of several pieces of materials;

JS series laser automatic counting machine The structural combination of the mechanical adjustment part and the embedded buckle design make the adjustment and cleaning of different products simple and time-saving during conversion;

Automatic fault diagnosis, comprehensive real-time monitoring, alarm and display;

With the function of parameter storage, all parameters can be directly called on the industrial control screen, which is very convenient and quick to change materials;

Cylinder positioning and bottle separation, fast and accurate, can be produced by single machine or by assembly line;

Complete equipment supporting materials (including equipment structure, principle, operation, maintenance, repair, upgrade and other explanatory materials) to provide adequate guarantee for normal operation of equipment;

JS series laser automatic counting machine The machine provides 8, 12, 16, 24, 32 and other different combinations of feeding tracks to meet different requirements for several pellets.

Relevant supporting equipment includes Capping machine 、 Labeling machine 、 Bottle sorting machine 、 Aluminum foil sealing machine Etc.