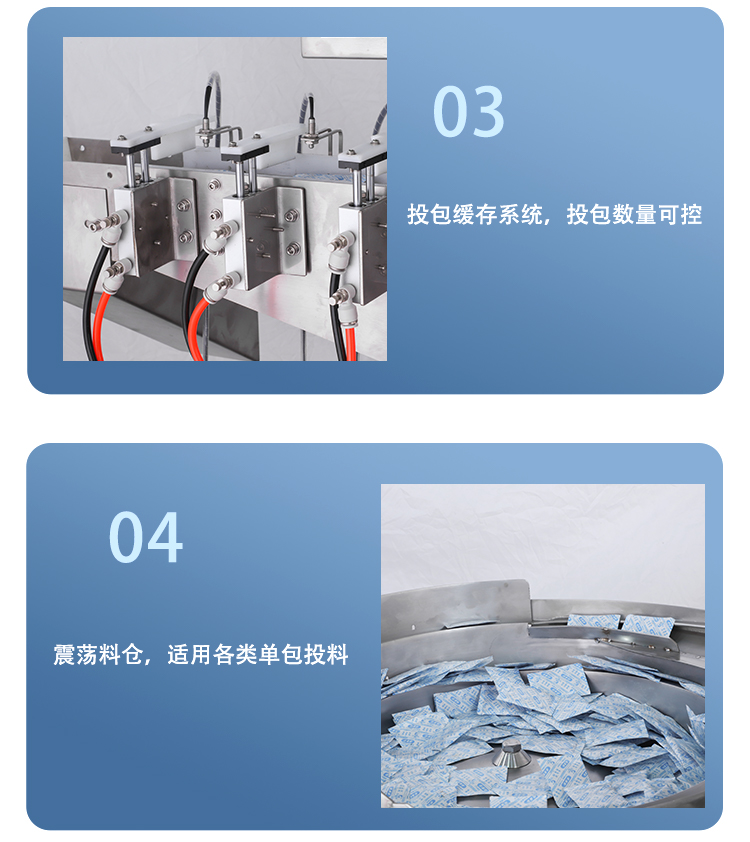

DI-50 desiccant feeding and packaging machine is a special feeding and packaging equipment for Chinese and western medicine tablets, pills, capsules and other solid medicines to be bottled, boxed or bagged into solid desiccants, which is used in the pharmaceutical industry, health products industry, food industry, chemical industry and other industries , complying with various GMP standards. The function of this machine is to shock several pieces of input products. Adopt perfect automatic program to control the input of desiccant; Control the feeding quantity and speed through precise positioning of the cursor.

This machine is mainly applicable to medicine, chemical industry, food and other industries. It is a special equipment to prevent the articles in the bottle from getting damp during transportation and storage. The machine stopper desiccant can avoid unnecessary pollution caused by manual stopper desiccant, and improve labor productivity.

Features of desiccant feeder

The operation is simple and convenient. Users can freely set the production capacity and choose different specifications of blanking packaging within the design range of the machine; Simple switching between different specifications and convenient adjustment;

It can be used with or embedded in the assembly line, and can be intelligently controlled with the previous and next processes, with good coordination, no need for special personnel to operate, and labor saving;

There is no package cutting link to ensure the integrity of the drying package; Avoid the risk of desiccant and deoxidizer damage, and reduce the unnecessary potential disputes caused by desiccant damage to food enterprises.

PLC control, Chinese and English dialogue control panel, can store ten groups of data, easy to adjust, and the operator can easily start;

The feeding of the drying pellet bag is stable and smooth, and the precise sensing of the optical electric eye ensures the accurate positioning of the drying pellet bag.

Optional data network interface for data storage and reading management.

Complete equipment supporting information (including equipment structure, desiccant feeder principle, desiccant feeder operation video, desiccant feeder maintenance, desiccant feeder maintenance, upgrading and other explanatory information), to provide full guarantee for normal operation of equipment.

Working speed of the package feeder: the maximum speed can reach 30~60 packages/minute; The photoelectric sensor automatically detects the speed of the production line and synchronously cuts off and releases;

Detection method: ultrasonic detection material package transverse seal;

Applicable bag size: length: 40~120mm, width: 30~100mm, thickness: 2~25mm;

Power supply: single-phase 220V, 50/60HZ, 1KW;

Machine dimension: 750 (L) * 700 (W) * 1600 (H) mm;

Scope of application: It is applicable to the automatic feeding of independent bags such as desiccants in food, daily necessities, chemical and pharmaceutical industries;

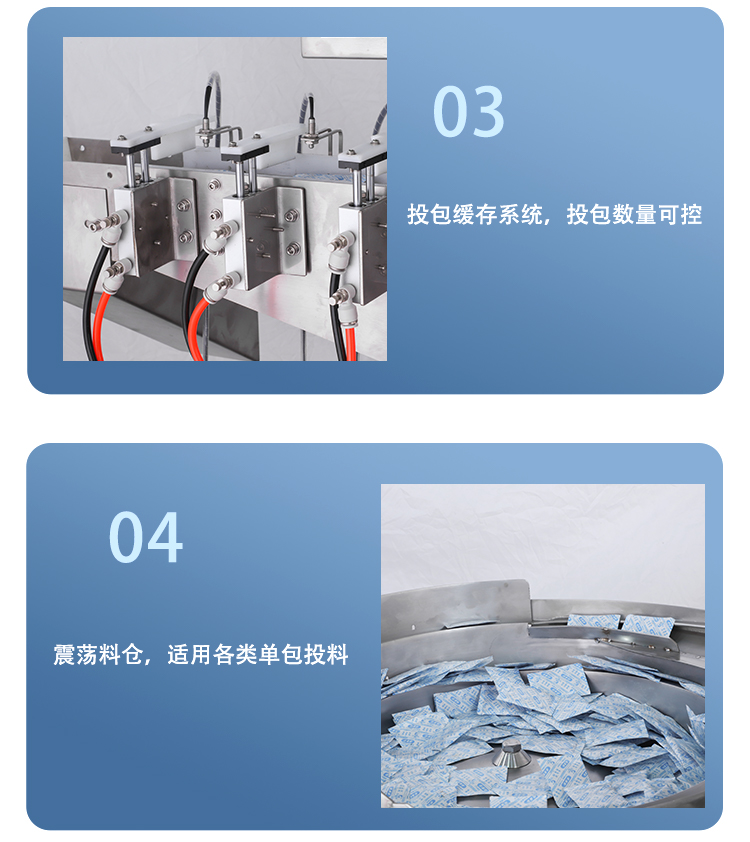

Main features of the package feeder:

1. Intelligent and efficient: automatic identification of material bags of different specifications and sizes, the maximum production speed can reach 240 bags per minute;

2. Easy to operate: the machine is very easy to operate, only need to install materials and start to run automatically;

3. Avoid breakage: There is no package cutting link to ensure the integrity of the deoxidizer package of the dryer ;

4. Hygiene and safety: the machine replaces manual feeding and meets the requirements of food hygiene and safety.

Main material of the packer: sus304 stainless steel

Fast and accurate input, convenient operation and intelligent control.