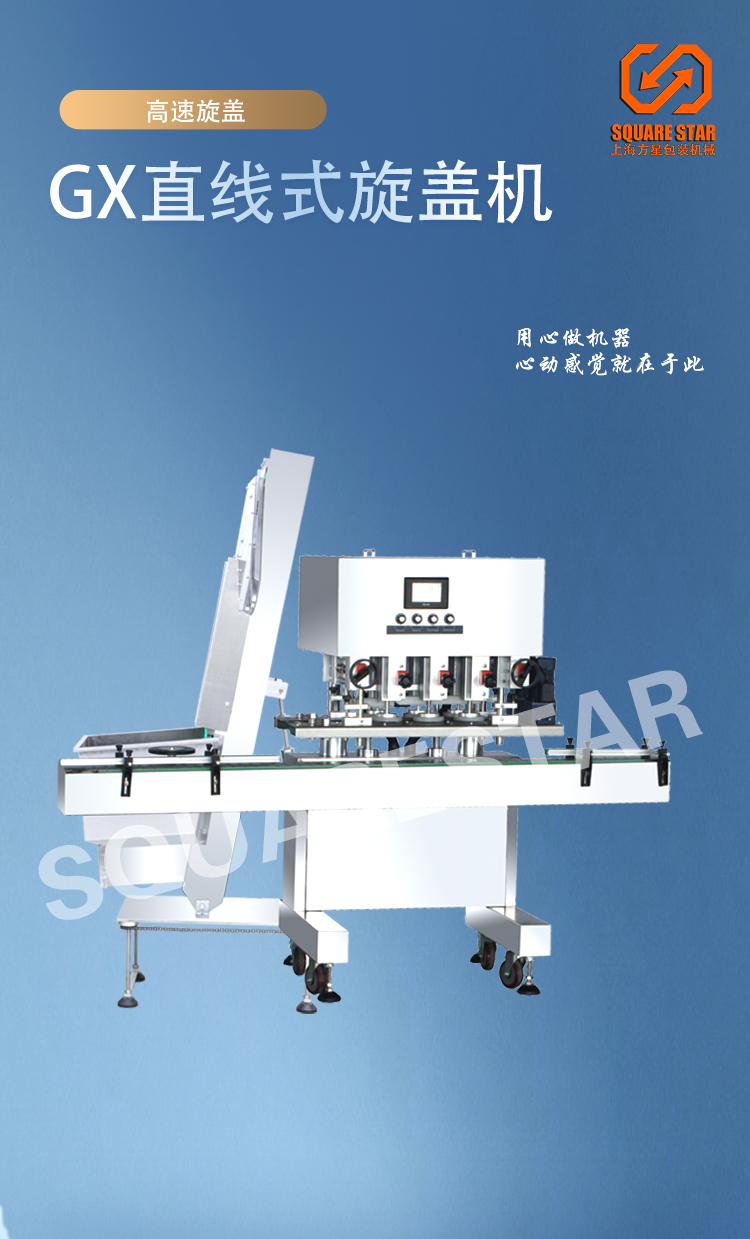

Equipment introduction:

GX Capping machine It is an automatic capping machine specially designed for pharmaceutical and food industries. The capping machine is composed of the capping machine lifting, capping, capping, conveying and capping machine removing mechanism. The bottles are automatically capped after entering the station. The bottle clamping mechanism of the capping machine clamps the bottles and then sends them to the capping mechanism to tighten the bottle caps. Because the bottle clamping belt and friction wheel are made of special materials, the durability of the equipment is guaranteed and the bottles and caps will not be damaged. This equipment carries out slant cap and slant cap detection after the thread is tightened, and rejects unqualified bottles to ensure the product qualification rate.

Features of GX capping machine:

Capping machine PLC control, Chinese and English interface touch screen, clear and understandable operation display;

The mode of "one capping wheel corresponds to one motor" ensures that the capping machine is stable, reliable, consistent in torque and easy to adjust even under long-term fatigue working conditions;

The bottle clamping belt can be adjusted separately to make it suitable for the capping of bottles of different heights and shapes;

Equipped with lifting motor, the automatic lifting of the capping machine can be realized;

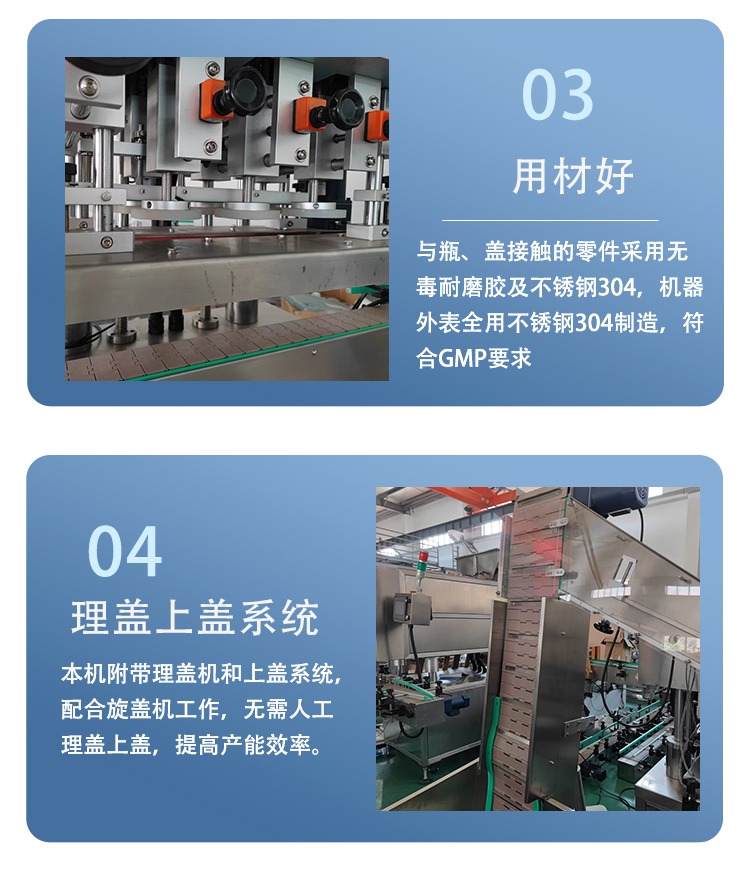

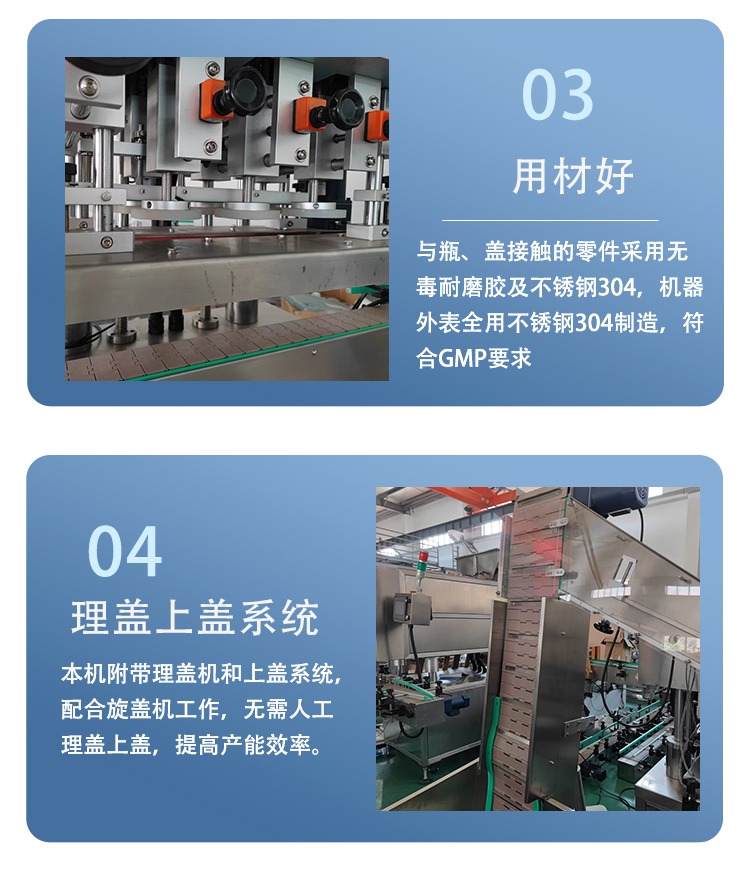

Parts in contact with bottles and caps shall adopt non-toxic synchronous belt and non-toxic cap spinning wheel;

The adjustment screw is equipped with digital position display function to reduce the difficulty of operation and avoid loose screw cap caused by inadequate adjustment;

Automatically manage and screw the lid, reducing the labor intensity of workers;

The body shell of the capping machine is made of 304 stainless steel, which meets GMP requirements;

Complete equipment supporting materials (including equipment structure, principle, operation, maintenance, repair, upgrade and other explanatory materials) to provide adequate guarantee for normal operation of equipment;

Magnetic powder torque limiter can be configured to effectively ensure product torque;

The capping machine can be equipped with an optional capping guide device, which is also suitable for capping the caps with pump heads;

Optional inspection mechanism for defective screw cap and aluminum foil free;

Optional data network interface for data storage and reading management.

Click to view Commissioning course of linear capping machine