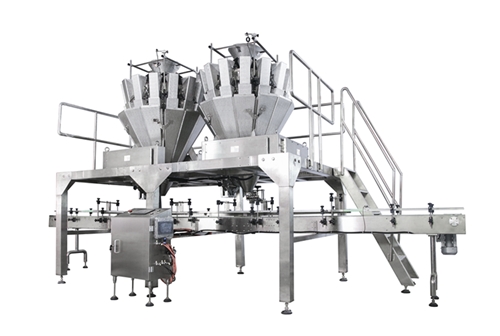

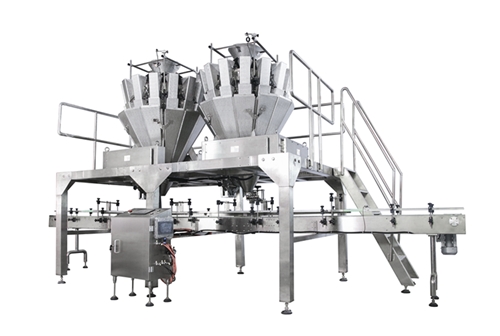

Liquid filling Capping machine Technical advantages and characteristics

With the continuous enrichment of liquid products, the utilization rate of liquid filling capping machines has also become higher. Whether it is food, daily chemical or pharmaceutical professions, any liquid product that wants to be packaged and sealed must be capped. Today's liquid filling capping machine market is constantly changing, and people have higher requirements for liquid filling capping machines, This has also brought challenges to the manufacturers of liquid filling capping machines. In order to win the purchase of users, some poor manufacturers imitate large manufacturers in product design, opportunistic in equipment quality, and then form a lack of integrity. Therefore, customers must identify the manufacturers of regular liquid filling capping machines when selecting.

Foshan Tan is a manufacturer with a history of 8 years. The technology of the liquid filling capping machine is now quite mature, and the after-sales service is also quite perfect. The product performance and operation are also cautious, stable and efficient. The following is a summary of the technical advantages and features of the liquid filling capping machine by Guangzhou Crown technicians. Let's get to know it quickly.

1. The filling and storage cylinder is made of 304 stainless steel, which adopts vertical servo screw filling and non-contact filling. The filling volume can be adjusted freely, and the quantitative filling accuracy is high.

2. High precision, the cam indexing mechanism provides the indexing plate with upper cover for positioning; The acceleration cam rolls to supply the lifting of the capping head; Constant torque screw cap; Peristaltic pump metering tank; Touch screen control.

3. No bottle, no filling, no inner plug, and no outer cover. It has the advantages of accurate positioning, stable transmission, protection of bottle cap, accurate measurement, and simple operation.

4. The equipment fully complies with GMP requirements. With microcomputer setting, accurate loading, convenient operation and active shutdown function, the machine can be automatically shut down when any track shows continuous non filling and non plugging conditions.