How to solve Photoelectric granulator Affected by dust

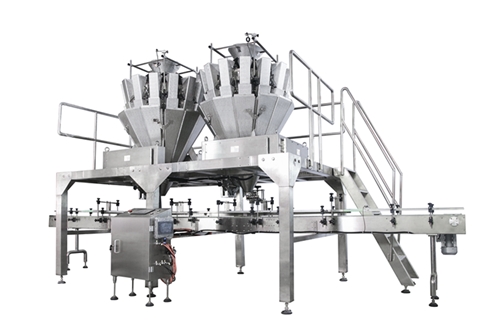

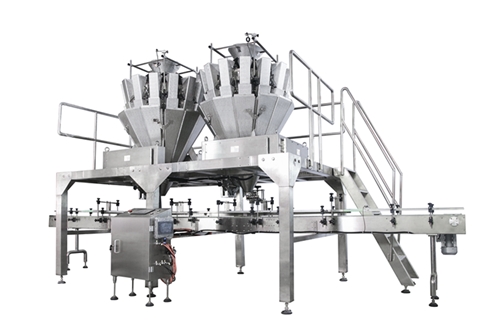

Granulator Widely used in the pharmaceutical and food industries, it is one of the key equipment in the production line of granular medicine cans. At present, there are mainly photoelectric particle counters in the domestic market, which use the photoelectric effect through the oscillating blanking operation. Packaging equipment with active counting. Although not limited by the numbering template, it can handle various shapes and different specifications. Users who have used the photoelectric counting machine will be affected by dust and the speed of the photoelectric counting machine. I should be well aware that when counting pills, pills and other dusty objects with the granulator, the problem of inaccurate counting will appear after a long time. Dargaard Digital Granule Machine is the world's first digital granulator, which uses the principles of high-speed imaging, whole stack counting and logical dispersion to solve the appeal problem. It is characterized by fast speed, accurate counting, simple structure and can detect fragments. Let's talk about why visual counting is better than photoelectric counting.

Visual granulator It breaks through the traditional method. The material flow is transported from the material tray in a single layer and flat condition, regardless of the single lane. When the pile falls, count through the imaging area. The first generation of visual particle counting method uses the compensation method. After the whole stack is counted, the compensation device controls the quantity of single pieces to make up the difference to the policy quantity. However, the difficulty is that the initial stack number needs to be controlled close to the policy number, and the items in rows need to be controlled separately when making up the difference, which is actually an extension of the traditional multi row- The channel method is also affected by some original problems. The latest generation of visual counting method does not need to make up the difference of counting items. The goods pile passes through a logical distributor, and the computer monitors the distribution status of the goods pile when entering the distributor, and allocates the policy quantity through a logical calculation method. The visual skill logical dispersion counting skill has the following advantages:

Visual counting mode, long-distance imaging, not affected by dust

High resolution, suitable for objects of different sizes, no blind spot

It can distinguish fragments and broken particles, and remove small piles of materials to avoid waste of production capacity

Articles do not need to be divided or separated. Single layer tray feeding and channel integration greatly improve the feeding density and production capacity

No need for high-speed gate, avoiding the risk of gate fragments, and no requirements for the cleanliness of compressed air

Small size, optimal capacity/floor area ratio, convenient for production line layout

The traditional electronic granulator adopts multi-channel transportation mode, which arranges the items in each channel into single row and single row, and triggers the corresponding photoelectric sensor to count when falling. When the cumulative quantity of each channel reaches the guideline value, the independent gates below the sensor are closed in turn, so that the cargo flow is stacked according to the guideline quantity. However, this counting method has been plagued by the following problems:

The photoelectric sensor needs to work close to the material, and its sensitivity is easily affected by the dust generated by the material

The sensor array is required to cover the width of the channel. There is a certain distance between sensors, and small objects have a certain probability of detecting blind spots.

The resolution of array sensor is limited, so fragments and fragments cannot be effectively identified

Multi stage oscillating disk is selected to disperse materials into multiple rows and occupy large plane space

The channel gate requires very high echo speed, and the cleanliness of compressed air is very high. Slight delay in door echo may damage objects or cause inaccurate stacking

Each channel of the granulator can only allow one project to pass by. If the passage is too small, it is not suitable for larger items. If the channel is too large, the volume of the equipment will increase, the chance of blind spot detection will increase, and the versatility of the equipment will be limited.